47

4.13.5

4.14.1

4.14.2

4.14.3

4.14 Maintenance and cleaning

4.14.1 – 4.14.3

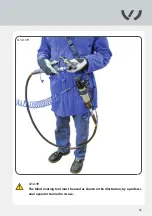

Disconnect the blind riveting tool from the operating unit and/or the high-pressure coupling.

Remove the high-pressure coupling from the Compact Booster.

4.13.5

To close, press the mandrel collector towards the riveting tool, as shown in the laser engraving.

Turn the mandrel collector to close the recovery aperture.