8

TOOLS REQUIRED and PRE INSTALLATION PROCEDURES

Tools Required:

25ft. Measuring Tape

Chalk Line and Chalk

Side Cutters (tin snips)

Floor Jacks – 2 (or engine crane)

Crow Bar

Metric and SAE Wrenches and Ratchet Sets

Metric and SAE Allen Key Sets

Hammer

Screwdrivers

4 ft. Level (and laser level)

Rotary Hammer Drill

¼ inch and ¾ inch diameter Masonry Drill Bits

Grout – 1 pail purchased locally (

see last page of this manual for reference information

)

Trowel, Float and Mixing Pail for hydraulic grout

Pre Installation Procedures

Before proceeding with installation, read the installation manual and insure all instructions

are fully understood and all component parts are accounted for.

IMPORTANT:

DO NOT CUT THE SHIPPING STRAPS HOLDING EACH RUNWAY

ASSEMBLY TOGETHER UNTIL INSTRUCTED TO DO SO

(step 3

– page 9)

.

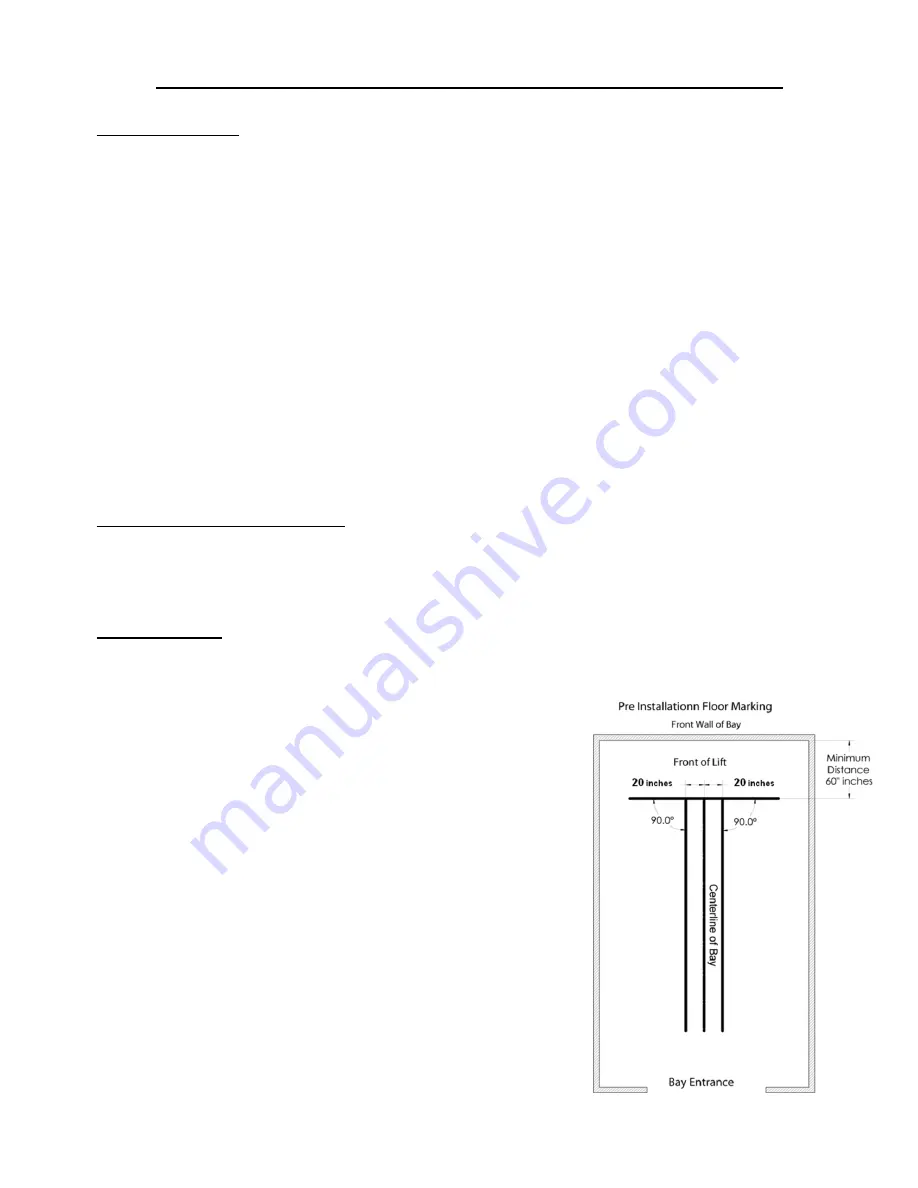

1. Identify bay center line near the front and mark the floor.

Also mark the center of bay entrance door. Connect

these two points with a chalk line. Locate the position

for front of the lift and draw a second chalk line at 90°

to the centerline

(this will be used to position the fronts of

both runway assemblies - refer to lift dimensions on page 7).

2. At the front, measure 20 inches out from either side

of the centerline and mark the floor. Near where the

rear of the lift will be, measure 20 inches out from

either side of the centerline and mark the floor. Using

these marks draw two parallel chalk lines the length of

the lift

(these will be used to position the inside edge of each

base frame).

Pre Installation Instructions continued on page 9