9

3. Carefully remove accessory box, (rolling air/hydraulic jack

(s)

, and

turnplate boxes if applicable) from on top of runway assemblies.

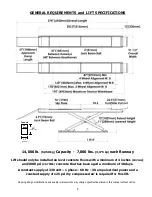

Identify top runway assembly

(see diagram to the right > >)

.

Move it to its proper position on the chalk lines you have marked.

Use extreme care not to damage preinstalled hydraulic, air and

electrical lines stored under the rear of each runway assembly.

Remove approach ramps from lower runway assembly and set

off to one side. Position second runway assembly on the chalk

lines you have marked. Confirm that turnplate pockets are at

the front of the bay and that all base frame edges are a minimum

6 inches from any floor seam. All anchor bolts must also be a

minimum of 6 inches away from any floor seam. Do not install if

floor has cracks or deterioration that could affect lift stability or

safety. The shop owner is responsible for confirming there are

no obstructions in the installation area like floor drains, under floor

piping or electrical conduit that could be damaged or would

prevent safe lift installation and secure lift anchoring. Check

ceiling for beams or heating ducts and walls for protruding

structures, etc.. Insure that the lift can be safely installed in the

position you have marked on the bay floor. Remove all packaging

material from installation area.

INSTALLATION PROCEDURE

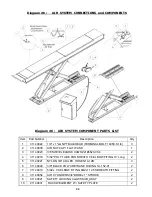

See the Installation and Parts Reference section of this manual for diagrams and parts lists

that will assist you during the installation process (pages 14 – 28). Use these diagrams and

parts lists together with the following written instructions. Insure the lift installation complies

with ANSI/ALI/ALIS, Safety Requirements for Installation and Service of Automotive Lifts.

1. Remove hydraulic, air and electrical lines from under the rear of each runway assembly.

Use extreme care not to damage any of these preinstalled items. Place on top of runway.

2. Unbolt steel shipping supports and remove from installation area.

3. Confirm that the front of both runways and inside base frame edges are on the chalk lines

you have marked. Also confirm that the runway assemblies are parallel to one another

(inside base frame distance front and rear must be equal - diagonal base frame distances front to

rear must also be equal)

. After confirming that the two runway assemblies are exactly

where they need to be, remove the shipping straps.

4. Unpack operator console and move to desired location

(reference diagram #1).

5. Carefully uncoil hydraulic, air and electrical lines and route them to the operator console

insuring there are no kinks.

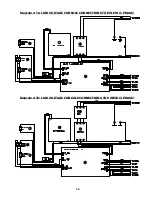

6. Connect hydraulic, air and electrical lines as follows:

(reference diagrams #3 to #8)

(i) Connect hydraulic line from passenger side of lift to console manifold marked

“passenger side”. Connect hydraulic line from driver side of lift to console manifold

marked “driver side”.

(ii) Connect passenger side return oil line

(5/32” black tubing)

to “T” fitting from accessory box.

Connect driver side return oil line

(5/32” black tubing)

to “T” fitting. Connect “T” fitting to

oil reservoir cap in console using

5/32”

black tubing from accessory box.

Installation Procedure continued on page 10