172-65427MA-05 (JH7RH-P/JH7RHT-P) 29 Sep 2016

12

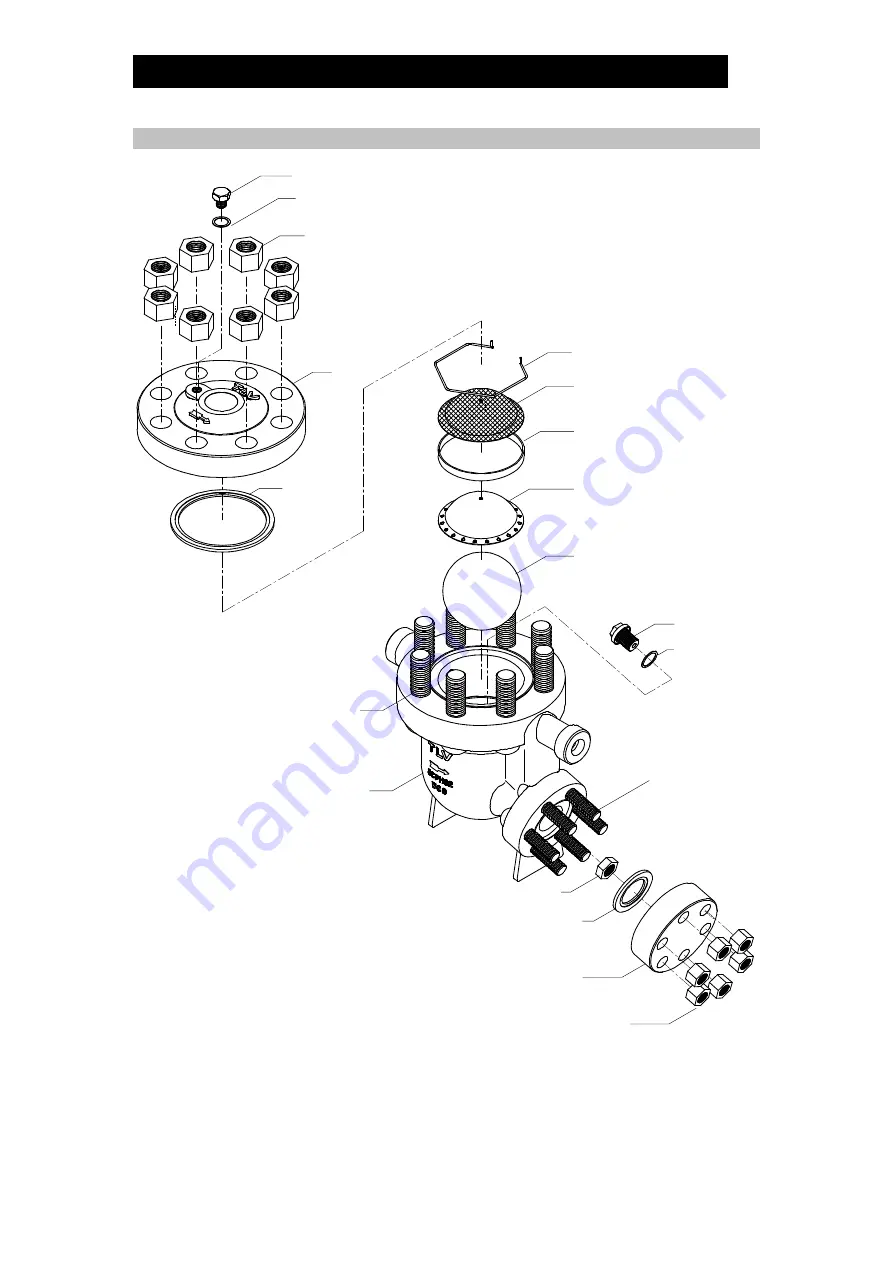

Exploded View

Cover Plug

Cover Plug Gasket

Cover Nut

Cover

Cover Gasket

Screen

Screen Holder

Float

Cover Bolt

Orifice Locknut

Outlet Cover Gasket

Outlet Cover Nut

Snap Ring

Screen Holder Retainer

Orifice

Orifice

Gasket

Outlet Cover

Outlet

Cover Bolt

Body