172-65126MA-10 (FLl5/FL21/FL32/FL5-C/FL21-C/FL32-C + BD2) 10 Mar 2017

16

BD2 Blowdown Valve Operation

1. The BD2 valve is in the closed position when the BD2 is shipped from the factory.

Before attempting to operate the BD2, reconfirm that the BD2 valve is still in the

closed position. Locate the blow outlet and, during operation, stand to the side and

well clear of it, as the jet of condensate or steam could cause burns.

2. Remain in the area the entire time the BD2 valve is in the open position. Before

opening the BD2 valve, grip the BD2 valve seat with a wrench and hold firmly in place

so that it will not rotate when the BD2 valve is loosened. Grip the BD2 valve with

another wrench and slowly loosen. Condensate and steam will discharge from the

blow outlet in a jet stream. Be careful not to loosen the BD2 valve so far that it

becomes removed from the BD2 valve seat. (If the valve stopper pin becomes

damaged, large quantities of steam will be discharged in a jet stream.)

3. Close the BD2 valve until the flow of fluid completely stops. If the flow of fluid does

not stop, re-open the BD2 valve (as in step “2”) to blow out any scale or dirt that may

be caught in the BD2. Re-tighten the BD2 valve until the flow of fluid stops

completely.

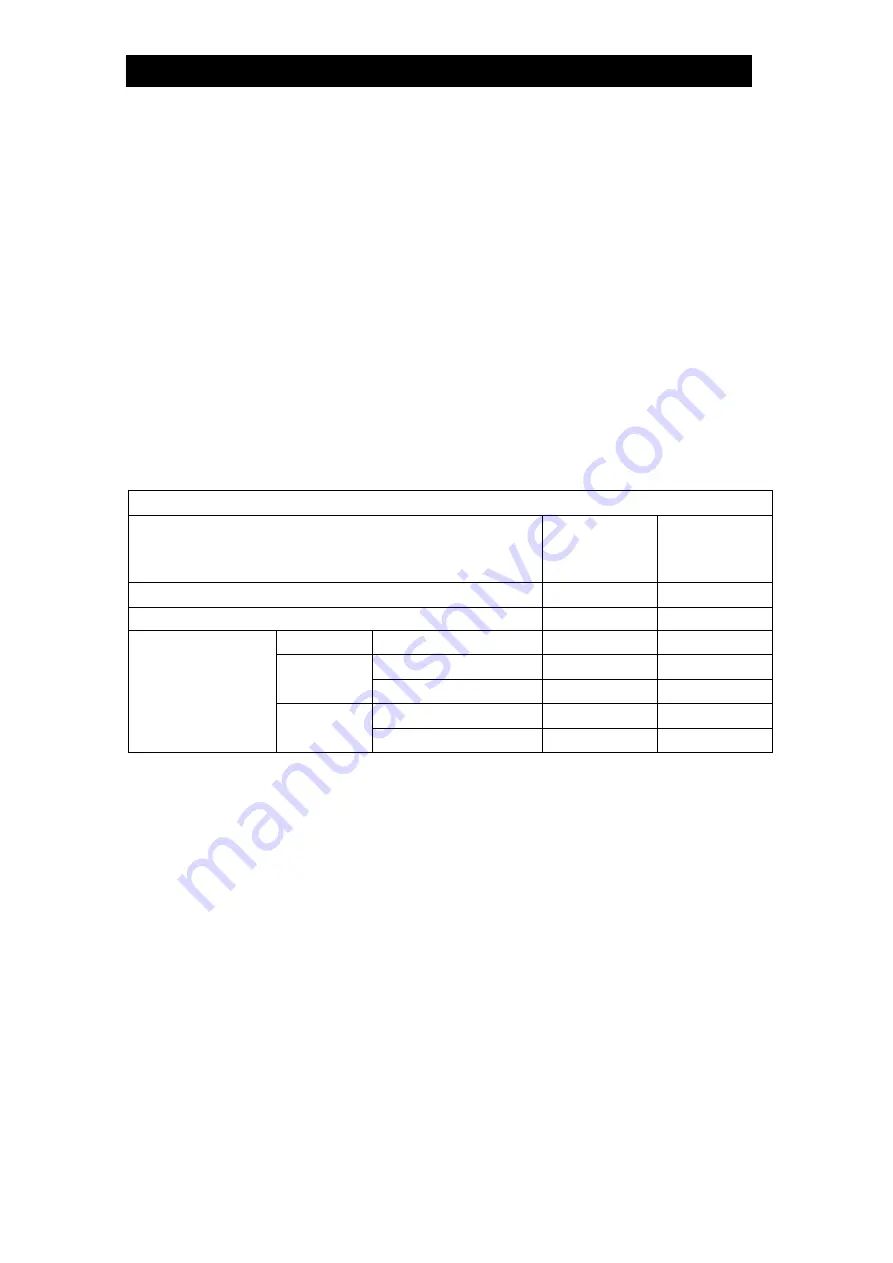

Tightening Torques and Distance Across Flats

Part Name

Torque

Distance

Across Flats

N

⋅

m

(lbf

⋅

ft)

mm

(in)

BD2 Valve

30

(22)

17

(

21

/

32

)

BD2 Valve Seat (Screen Holder) (when F46 is used)

100

(73)

30

(1

3

/

16

)

BD2 Valve Seat

(Screen Holder)

(when F32 is used)

Flanged

15 – 25 mm (

1

/

2

– 1

in)

60

(44)

22

(

7

/

8

)

Screwed

15

⋅

20 mm (

1

/

2

,

3

/

4

in)

60

(44)

22

(

7

/

8

)

25 mm

(1 in)

150

(110)

38

(1

1

/

2

)

Socket

Welded

15

⋅

20 mm (

1

/

2

,

3

/

4

in)

60

(44)

22

(

7

/

8

)

25 mm

(1

in)

150

(110)

38

(1

1

/

2

)

NOTE: Avoid the use of excessive tightening torques, as threaded parts

may become damaged.

(1 N

⋅

m

≈

10 kg

⋅

cm)