9

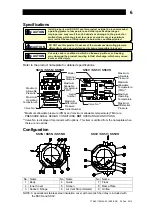

Troubleshooting

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

If the trap fails to operate properly, use the following table to locate the cause and

remedy.

Problem Cause Remedy

The trap operating pressure

exceeds the maximum specified

pressure or there is insufficient

pressure differential between the

trap inlet and outlet

Compare specifications and

actual operating conditions

The piping is clogged with rust and

scale

Clean the piping

The capacity of the trap is

insufficient

Compare specifications and

actual operating conditions

No condensate is

discharged (blocked) or

discharge is poor

Steam-locking has occurred

Perform a bypass blowdown or

close the trap inlet valve and

allow the trap to cool

Improper installation orientation

Correct the installation

Steam is discharged or

leaks from the outlet

(blowing) (steam leakage)

Trap vibration

Lengthen the inlet piping and

fasten it securely

Steam is leaking from a

place other than the outlet

The outside of the trap has

sustained damage

Replace with a new trap

Float becomes damaged

Water hammer has occurred

Study and correct the piping

NOTE: SS3N

SS3V / SS5N

SS5V / SS5NH

SS5VH steam traps are of all-welded, single unit

construction, so they cannot be repaired.

172-65119MAJ-03 (SS3/SS5) 25 Feb 2014