5

Operation

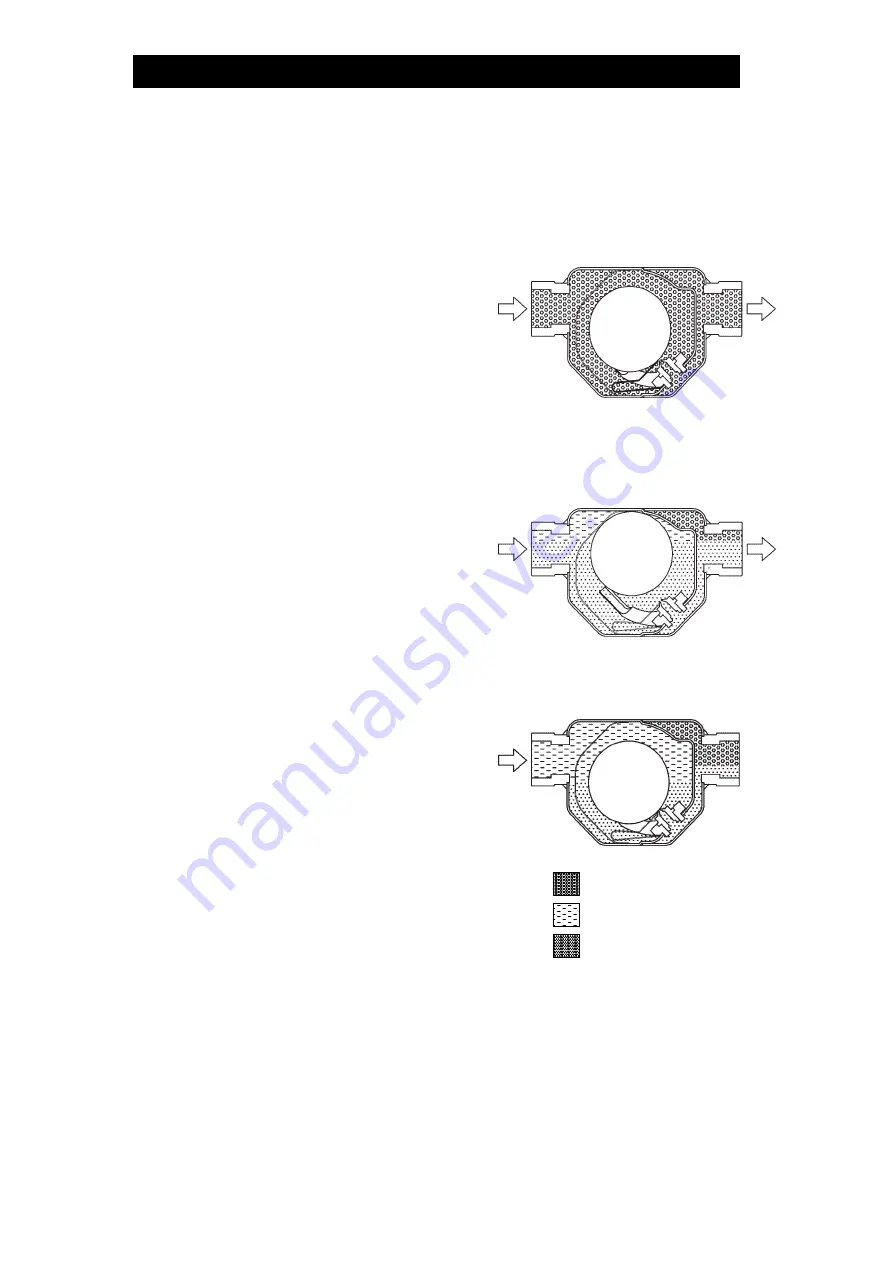

Principles of air and condensate discharge:

1. Start-up Air and Cold Condensate

Discharge

At start-up, before steam is supplied, the

system is cold and the bimetal air vent strip

is expanded, holding the float off of the

orifice. This allows for the rapid discharge

of air and cold condensate through the

orifice when steam is first supplied to the

system. After the discharge of initial air and

cold condensate, the heat of the inflowing

steam and condensate cause the bimetal

air vent strip to contract.

2. Condensate Discharge

As steam is supplied, condensate flow

begins. The rising condensate level causes

the float to rise due to buoyancy, opening

the orifice and allowing condensate to be

discharged.

3. Closed Position

When the condensate flow rate decreases,

the float falls, closing off the orifice

opening. A water seal is maintained at all

times over the orifice to prevent steam loss.

Air

Steam

Condensate

172-65119MAJ-03 (SS3/SS5) 25 Feb 2014