TM INDUCTION HEATING

22

ST PRO 2.3 |

If in any doubt, isolate the induction heater and contact your local

distributor. You can find the contact details for your nearest distributor

on

www.tminductionheating.com/distributors

.

If a loud vibrating noise is heard:

`

Stop the heating cycle by pressing the start/stop button.

`

Are the contact surfaces clean and greased sufficiently?

`

Are the yokes 100% in contact with the surface? If this is not the case

adjust the yoke with instructions below.

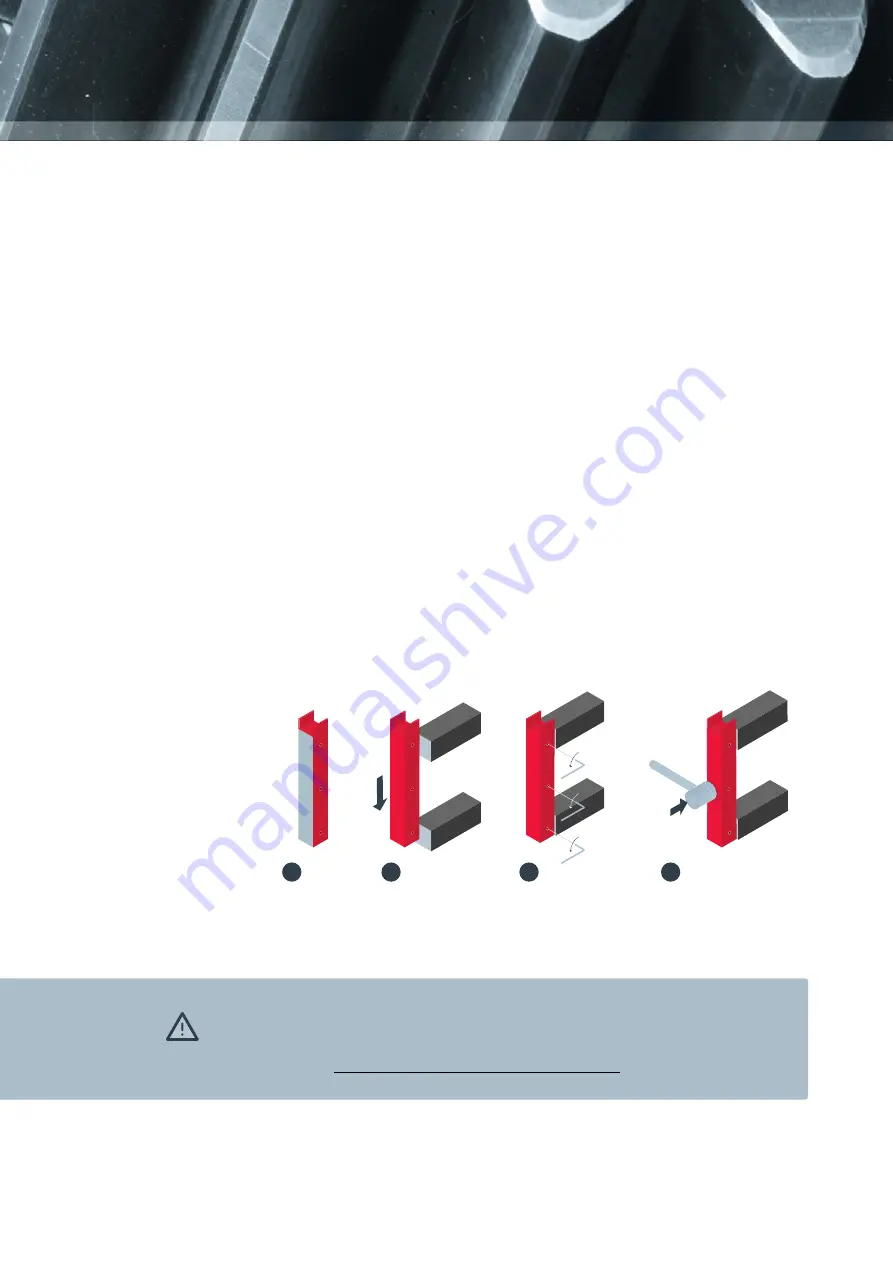

1. Check if the machine milled surface is smooth.

2. Place yoke or pivoting yoke on the heater.

3.

Unscrew the screws in the yoke and pivoting point a quarter turn.

4. Turn on the heater and the yoke will set itself or use a nylon hammer.

MALFUNCTION

7

ADJUSTING

THE YOKE

4

3

2

1

5. Fasten screws, turn off heater and the yokes are now adjusted.

WARNING