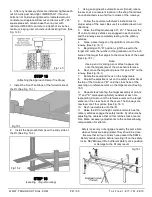

STEP 17

(Bleeding)

1.

Lift must be fully lowered before changing or adding

fluid.

2.

Raise and lower lift six times. The Cylinder is self-

bleeding. After bleeding system, fluid level in Power

Unit reservoir may be down. Add more fluid if

necessary to raise lift to full height. It is only necessary

to add fluid to Raise lift to full height.

3.

To pressure test, run lift to full rise and run motor

for approximately 3-seconds after lift stops. This will

place pressure on the hydraulic system. Stop and check

all fittings and hose connections. Tighten or reseal if

required.

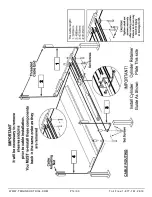

POST-INSTALLATION CHECK-OFF

Columns properly shimmed and stable

Anchor Bolts tightened

Pivot / Sheave Pins properly attached

Electric power supply confirmed

Cables adjusted properly

Safety Locks functioning properly

Check for hydraulic leaks

Oil level

Lubrication of critical components

Check for overhead obstructions

All Screws, Bolts, and Pins securely fastened

Surrounding area clean

Operation, Maintenance and Safety Manuals

on site.

Perform an Operational Test with a typical vehicle

STEP 18

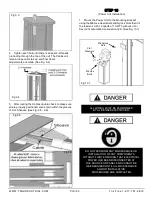

(Lift Operation Safety)

•

DAILY inspect your lift. Never operate if it

malfunctions or if it has broken or damaged parts. Use

only qualified lift service personnel to make repairs

.

•

THOROUGHLY train all employees in use and care of

lift, using manufacturer’s instructions and “Lifting It

Right” and “Safety Tips” supplied with the lift.

•

NEVER allow unauthorized or untrained persons to

position vehicle or operate lift.

•

PROHIBIT unauthorized persons from being in shop

area while lift is in use.

•

DO NOT permit anyone on lift or inside vehicle when it is

either being raised or lowered.

•

ALWAYS keep area around lift free of tools, debris,

grease and oil.

•

NEVER overload lift. Capacity of lift is shown on

nameplate affixed to the lift.

•

DO NOT stand in front of the vehicle while it is being

positioned in lift bay.

•

DO NOT block open or override self-closing lift

controls; they are designed to return to the “Off” or

Neutral position when released.

•

ALWAYS remain clear of lift when raising or lowering

vehicles.

•

ALWAYS use safety stands when removing or installing

heavy components.

•

DO NOT go under raised vehicle if safety locks are not

engaged.

•

NEVER LEAVE LIFT IN ELEVATED CONDITION

unless all Safety Locks are engaged.

•

AVOID excessive rocking of vehicle while on lift.

•

ALWAYS CLEAR AREA if vehicle is in danger offalling.

•

ALWAYS REMOVE tool trays, stands, etc. before

lowering lift.

•

ALWAYS RELEASE safety locks before attempting to

lower lift.

•

DO NOT position yourself between a wall and the lift. If

the vehicle falls in that direction, you may be severely

injured or killed.

To Raise Lift;

1.

Position vehicle tires in the center of each Runway.

2.

Set parking brake and use Wheel Chocks to hold

vehicle in position.

3.

Before raising vehicle, be sure all personnel are clear

of the lift and surrounding area. Pay careful attention to

overhead clearances.

TO AVOID PERSONAL INJURY AND/OR PROPERTY

DAMAGE, PERMIT ONLY TRAINED PERSONNEL TO

OPERATE LIFT. AFTER REVIEWING THESE

INSTRUCTIONS, PRACTICE USING LIFT CONTROLS

BY RUNNING THE LIFT THROUGH A FEW UNLOADED

CYCLES BEFORE LOADING VEHICLE ON LIFT.

NEVER

RAISE JUST ONE END, ONE CORNER,

OR ONE SIDE OF VEHICLE.

WWW.TMGINDUSTRIAL.COM

P22/33

Toll Free:1-877-761-2819