CAUTION!

If you are not completely familiar with automotive lift

maintenance procedures; STOP: Contact factory for

instructions. To avoid personal injury, permit only

qualified personnel to perform maintenance on this

equipment.

W W W . T M G I N D U S T R I A L . C O M

P 2 0 / 2 8

T o l l F r e e : 1 - 8 7 7 - 7 6 1 - 2 8 1 9

TO LOWER THE LIFT

WARNING!

When lowering the lift PAY CAREFUL ATTENTION that

all personnel and objects are kept clear.

ALWAYS keep a visual line of site on the lift AT ALL

TIMES. ALWAYS make sure that ALL LOCKS are

disengaged. If one of the locks inadvertently locks on

descent the lift and/or vehicle may disrupt causing

personal injury or death.

1.

Remove all tools or other objects from the lift area.

2.

Raise lift off safety locks. Make sure you raise the lift

by at least two inches to allow adequate clearance for

the locks to clear.

3.

Confirm safety lock is in unlocked position.

4.

Push LOWERING valve handle to lower. Do not

override self-closing lift controls.

5.

Remain clear of lift when lowering vehicle.

Observe pinch point warning decals.

6.

Remove adapters from under vehicle and arms to

full drive-thru position before moving vehicle.

7.

If lift is not operating properly, DO NOT use until

adjustment or repairs are made by qualified lift

service personnel.

MAINTENANCE INSTRUCTIONS

•

Always keep bolts tight. Check periodically.

•

Always keep lift components clean.

•

Always if oil leakage is observed, call local service

representative.

•

Always if electrical problems develop, call local

service representative.

•

Always replace ALL FAULTY PARTS before lift

is put back into operation.

•

Daily: Make a visual inspection of ALL

MOVING PARTS and check for excessive

signs of wear.

•

Daily: Check Safety Locks to ensure they are in

good operating condition.

•

Daily: Check pivot points and hinges for

wear. Replace worn parts as required with

genuine parts.

•

Daily: Inspect adapters for damage or

excessive wear. Replace as required with

genuine parts.

•

Weekly: Lubricate any rollers with general

purpose oil or WD-40. Lubricate arm Hinge Pins

with grease.

•

Weekly: Check bolts and pins to ensure

proper mounting.

•

Monthly: Lubricate locking latch shafts. Push latch

handle several times for oil to penetrate pivot points.

•

Semi-Annually: Check fluid level of lift power unit

and refill if required per lift installation instructions.

•

Replace all caution, warning or safety related

decals on the lift if unable to read or missing.

•

Refer to ANSI/ALI ALOIM booklet forperiodic

inspection checklist and maintenance log sheet.

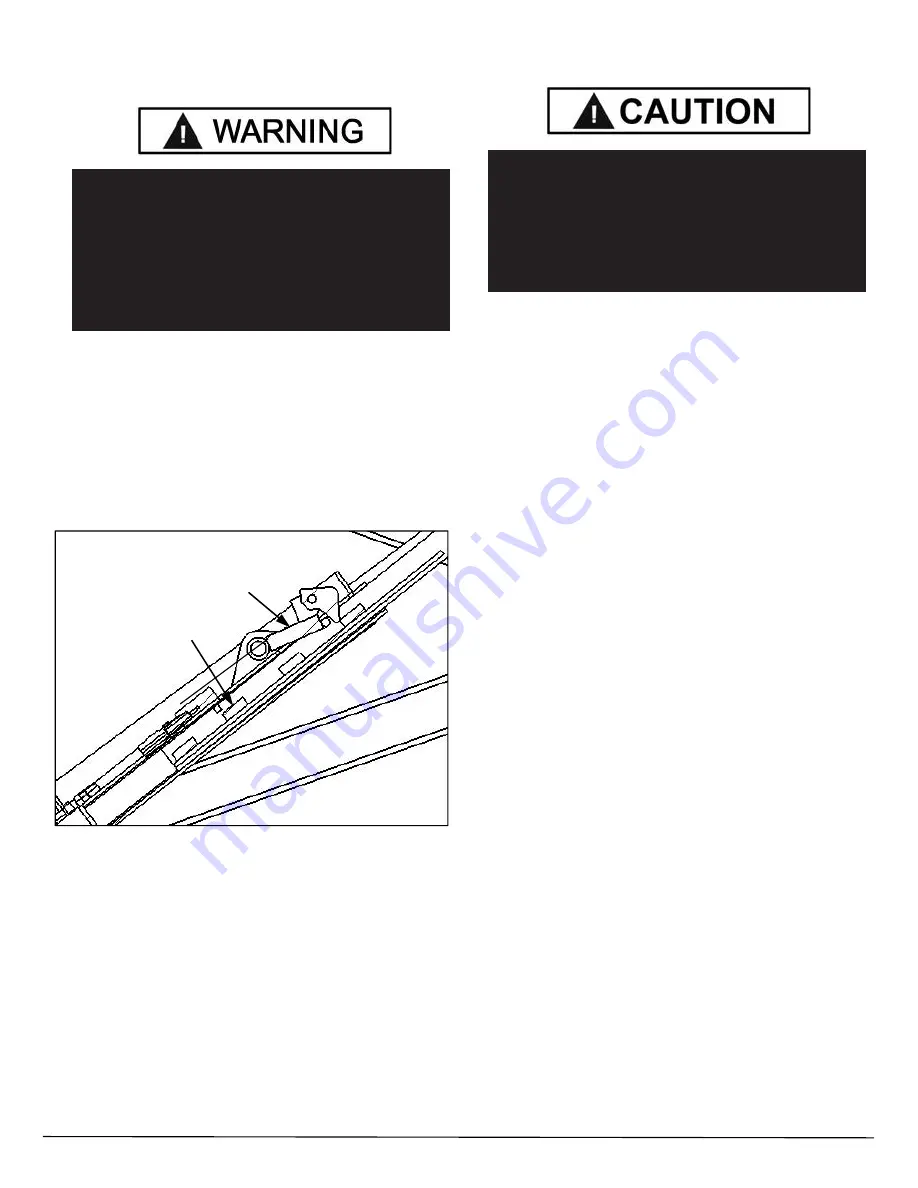

Safety Unlocked

Safety Blocks

Safety Pin