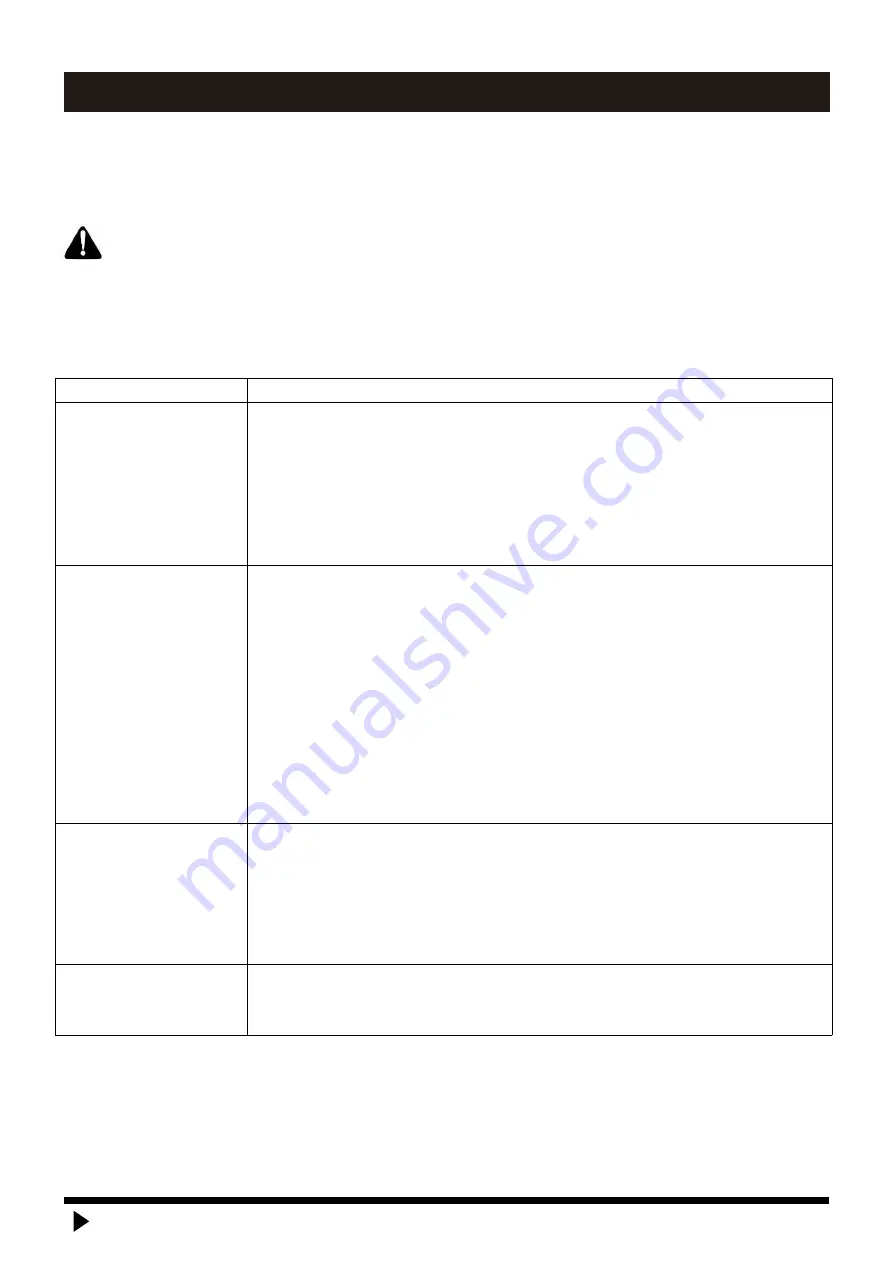

TROUBLESHOOTING

Most problems are easy to fix. Consult the Troubleshooting Table below for common problems and their

solutions. If you continue to experience problems, contact the dealers in your area.

WARNING

Before performing any maintenance procedure or inspection, stop the engine, wait five minutes to allow all

parts to cool. Disconnect the spark plug wire, keeping it away from the spark plug.

Troubleshooting Table

SYMPTOM

POSSIBLE CAUSE

The engine won’t start.

(Please refer to the

engine user manual

for engine-specific

procedures.)

Is the ignition switch in the “ON” position?

Is the fuel shut-off valve on?

Are you using fresh, clean gas? If the gas is old, change it. Use a fuel stabilizer

if you keep gas longer than 30 days.

Is the spark plug clean? If the spark plug is dirty or cracked,

change it. If it’s

oily, leave it out, hold a rag over the plug hole and pull the recoil cord several

times to blow out any oil in the cylinder, then wipe off the plug and reinsert it.

The engine lacks power

or is not running

smoothly.

(Please refer to the

engine user manual

for engine-specific

procedures.)

Check that the Throttle Lever is in the “Run” position.

Is the air filter clean? If it’s dirty, change it following the procedure in the

engine manufacturer’s owner’s manual.

Is the spark plug clean? If it’s fouled or cracked, change it. If it’s oily, leave it

out, hold a rag over the plug hole and pull your recoil cord several times to

blow out any oil in the cylinder, then wipe off the plug and reinsert it.

Are you using fresh, clean unleaded gas? If it’s old, change it. Use a fuel

stabilizer if you keep gas longer than 30 days.

Does your engine have the right amount of clean oil? If it’s dirty, change it

following the procedure in the engine manufacturer’s owner’s manual.

Check the oil level and adjust as needed.

Engine smokes.

(Please refer to the

engine user manual

for engine-specific

procedures.)

Check the oil level and adjust as needed.

Check the air filter and clean or replace if needed.

You may be using the wrong oil—too light for the temperature. Refer to your

Engine Owner’s Manual for detailed information.

Clean the cooling fins if they’re dirty.

Machine does not seem

to have full chipping

power.

The belts may be too loose and slipping. Adjust or replace belts as need.

www.tmgindustrial.com

19/21

Toll Free:1-877-761-2819