www.tmgindustrial.com

20/35

Toll Free:1-877-761-2819

OPERATING ESSENTIALS

1. Attentions during in use

1. When start job, lift the rotary tiller, make sure accelerate the blade axle to the rated speed, and then drop the

tiller until the blade buried to the desired depth. Do not accelerate the shaft or drop the tiller after buried the

blade, to avoid overloading the tractor or damaging the blades.

2. Within the job, should try to drive slowly, so that can guarantee the work quality, crushing clouds and reduce

mechanical wear and tear, pay attention to whether there is any noise or metal percussion sounds, and

observe the pulverizes, deep tillage situations, if there is any exception should immediately stop work and

check, after the exclusion can continue operations.

3. Stop work when turn a corner, raise the tiller until the blade off the ground, and reduce tractor throttle to

avoid damage to the blade. When raise rotary tiller, make sure the universal -joint tile angle less than 30

degrees, it may cause noise if over the degrees and then premature wear or damage

4. When drive in reverse, crossing the ridge and transfer to other land, should raise the tiller to the highest

position, and cut off the power to avoid any damages, if more to far away , make sure to use lock device fix

the machine well.

5. After working, should maintenance the machine, remove dirt and debris, check the connection fastening

case, each point lubricant filling oil, to prevent aggravating wear.

2. Rotary tiller adjustment

1. Side adjustment, park the tractor with rotary hoe in flat ground, drop the rotary hoe until the blade 5cm

from the ground, check the the tip for sides blades have the same distance to ground, in order to

ensure

the blade axle in straight level, tillage depth evenly.

2. Front and rear adjustment. When drop the rotary tiller to the required depth, observe universal joint

angle and the rotary tiller angle is in a near horizontal position. If the angle is too large, adjust the rod,

so that rotary hoe in the horizontal position.

3. Lifting height adjustment. Rotary job, angle does not allow more than 10 degrees, When drive in

reverse, the angles are not allowed more than 30 degrees. Pay special attention when lifting. For

increased again rotary tiller, the universal joint power should be removed.

⚠

Danger

● Don't touch blade when in operation, injuries may occur.

● In high-speed rotating operation, the stone will fly out, take close attention to yourself and the problem

around.

⚠

Warning

● Exceed the PTO speed may cause injury accident, make sure to operate within the specified speed.

● Keep low-speed operation in tilt ground.

Note the front and surroundings while driving,

Summary of Contents for TMG-RT83

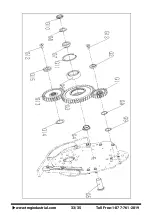

Page 24: ...www tmgindustrial com 24 35 Toll Free 1 877 761 2819 2 Hood assembly ...

Page 26: ...www tmgindustrial com 26 35 Toll Free 1 877 761 2819 ...

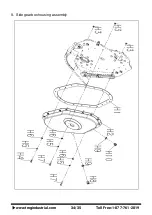

Page 27: ...www tmgindustrial com 27 35 Toll Free 1 877 761 2819 4 Left Panel Assembly ...

Page 29: ...www tmgindustrial com 29 35 Toll Free 1 877 761 2819 ...

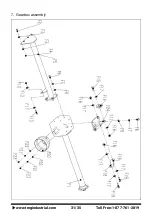

Page 31: ...www tmgindustrial com 31 35 Toll Free 1 877 761 2819 7 Gearbox assembly ...

Page 33: ...www tmgindustrial com 33 35 Toll Free 1 877 761 2819 ...

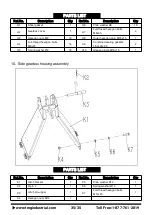

Page 34: ...www tmgindustrial com 34 35 Toll Free 1 877 761 2819 9 Side gearbox housing assembly ...