W W W . T M G I N D U S T R I A L . C O M

P 1 4 / 4 1

T o l l F r e e : 1 - 8 7 7 - 7 6 1 - 2 8 1 9

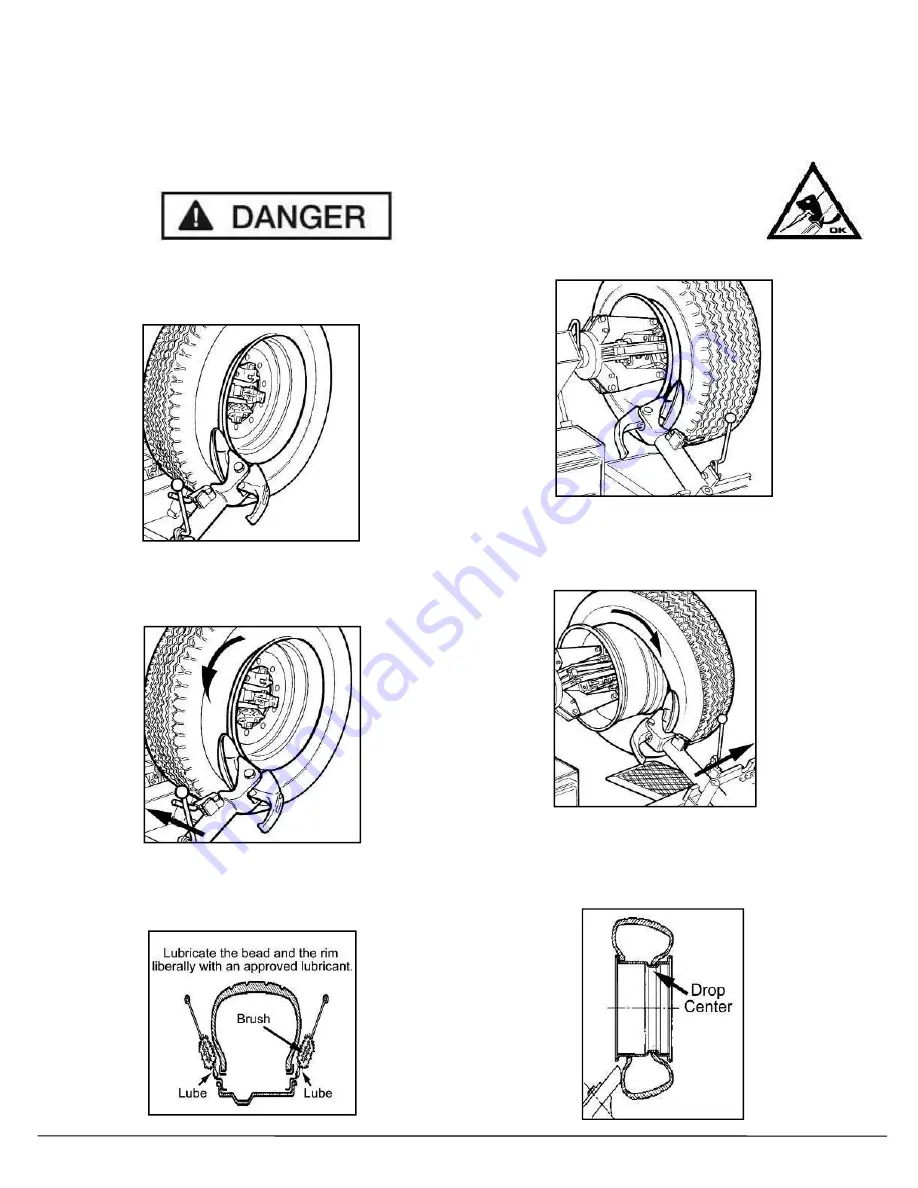

Demounting Tubeless Truck Tires (Up to 13”)

Tubeless truck tires are usually mounted on drop-center

rims. It is possible to demount these tires simply by

pressure, and with proper lubrication

1. Remove all of the wheel-weights from the rim. Remove

the valve stem or core and deflate the tire.

ALWAYS

remove valve core to deflate tire beforeservicing.

2. Position the bead loosener disc or tubeless roller on the

outside bead of the tire as shown below.

3. Lift or lower the chuck so that the bead loosener disc or

tubeless roller remains close to the rim edge. Turn the chuck

counterclockwise while at the same time moving the tool

holder sliding carriage slowly left.

5. Bring the tool carrier arm and disc back from the edge of

the wheel then release the hook and raise the tool holder

arm to the rest position.

6. Press the tool lock handle to unlock the tool head and

turn the head 180° until it locks automatically and the disc is

facing to the right.

7. Lower the tool-holder arm into its working

position and allow it to lock securely.

8. Position the bead loosener disc close to the rim edge

9. Turn the chuck counterclockwise while at the same time

moving the tool holder sliding carriage slowly right until the

inside bead is fully detached.

4. Continue to turn the chuck and lubricate the bead and the

rim liberally with an approved lubricant. Use only approved

lubricants for tires and wheels. Continue until the first bead

is fully detached.

10. Continue rotating the chuck, moving tool holder

carriage towards the outside until the beads arecompletely

demounted. Ensure that the outer bead slides into the

drop center opposite to the tool, otherwise the demounting

operation is impossible.