W W W . T M G I N D U S T R I A L . C O M

P 1 7 / 4 1

T o l l F r e e : 1 - 8 7 7 - 7 6 1 - 2 8 1 9

4. Re-attach the mounting clamp to the outer rim flange with

the valve forward of the mounting clamp.

5. Rotate the chuck clockwise until the tire iscompletely

mounted.

Always stop the chuck before one complete turn is made

to avoid personal injury or serious damage to themounting

clamp and/or rim.

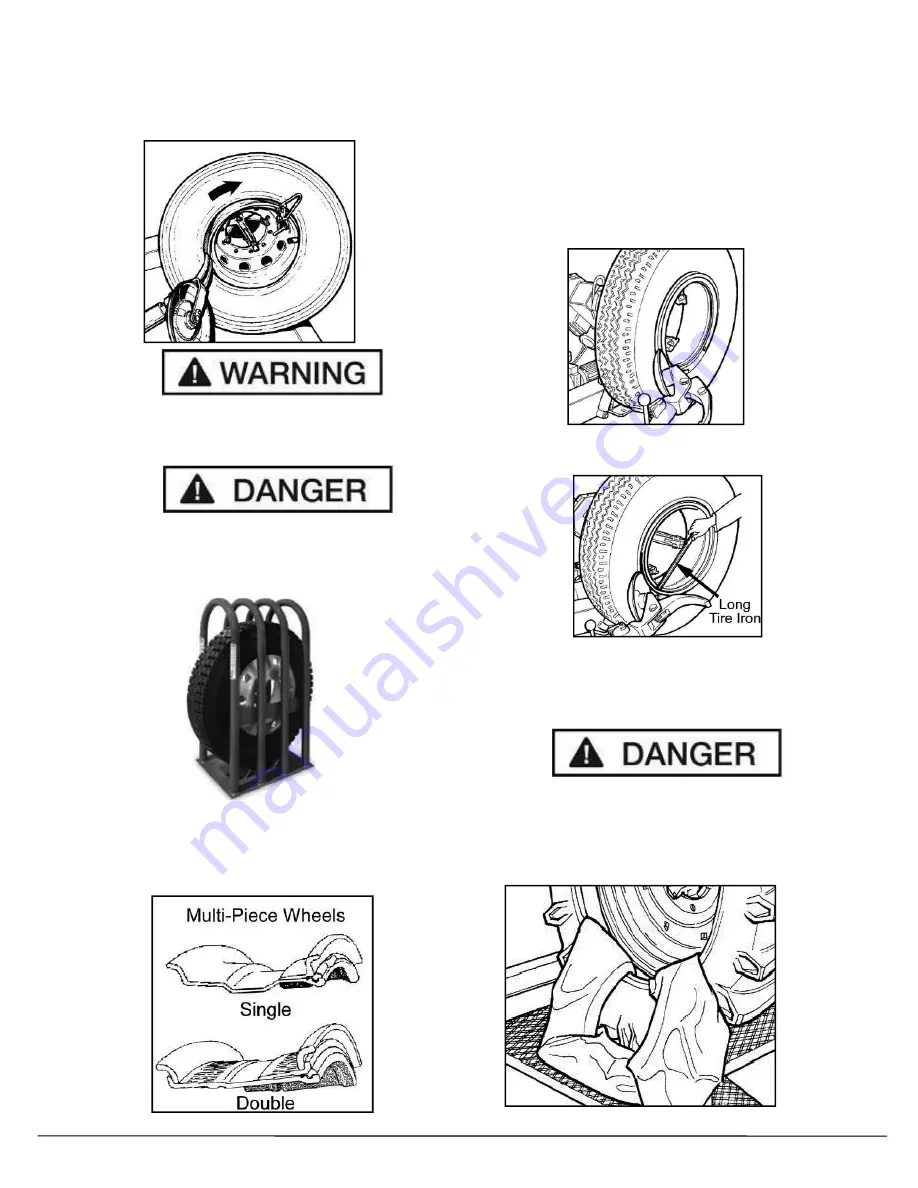

Do not inflate the tire on the machine. This machine is

not an inflation device. For inflation place the wheel in

an approved inflation restraint device. Refer to OSHA

standard number 1910.177.

Demounting Tires From Multi-Piece

Rim/Wheel Assemblies (Tube Type Tires)

The multi-piece split-rim/wheel assembly can be in single or

multi-piece configurations.

NOTE:

Always consult the tire /wheel manufacturer for information

if you are uncertain of Rim/wheel configuration.

1. Remove all wheel-weights from the rim. Remove the

valve stem or core and deflate the tire completely.

2. Position the tool close to the rim edge.

3. Turn the chuck counterclockwise and loosen the bead as

described previously. Do not lubricate.

4. To remove the lock ring, squeeze one edge with the tire

iron bar and place the bead loosener disc as shown.

5. Turn the chuck clockwis (or counterclockwise) until the

lock ring is completely removed.

No one should stand in front of the wheel

when removing the lock ring.

6. Continue to demount all components of the rim manually

or with the disc tool. When loosening the inner bead besure

not to damage the valve stem.