WWW.TMGINDUSTRIAL.COM

17 / 27

dŽůů&ƌĞĞ

:1-887-761-2819

O P E R A T I O N

g. Ensure your wood chip pile is contained and doesn't affect the immediate work area.

Unplugging

Although the machine is designed to handle a wide variety of material without any problem, occasionally it

plugs. When the machine plugs, follow this procedure to unplug:

a. Clear the area of bystanders, especially small children.

b. Turn off the hydraulics, stop the engine, remove the ignition key and place it in your pocket and wait for

all moving parts to stop before unplugging.

c. Pull the material out of the feed hopper. Be sure all the material is out, and nothing is jammed or wedged

between the input opening and the rotor.

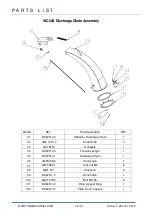

d. Pull the material out of the discharge hood. Use a stick to poke loose any material jammed into the

discharge hood. Do not allow anything to remain in this area.

e. Check that everyone is clear of machine before restarting engine.

f. Start the engine turn on the hydraulics, and resume working.

Severe Plug

a. Clear the area of bystanders, especially small children.

b. Turn off the hydraulics, stop the engine, remove the ignition key and place it in your pocket or remove

spark plug wire, and wait for all moving parts to stop before unplugging.

c.

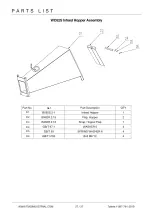

Loosen the feed hopper anchor nuts and raise the feed hopper.

d. Remove jammed material from inside the rotor compartment.

e. Clean out the discharge area/rotor.

f. Open the upper rotary housing and clean out the housing.

g. Be sure to turn the rotor by hand to be sure there is nothing jammed between the rotor and stationary

blades.

h. Close, install and fold down all components opened to unplug. Tighten fasteners to their specified

torque.

i.

Check that everyone is clear of machine before restarting engine.

j.

Start the engine turn on the hydraulics and resume working.