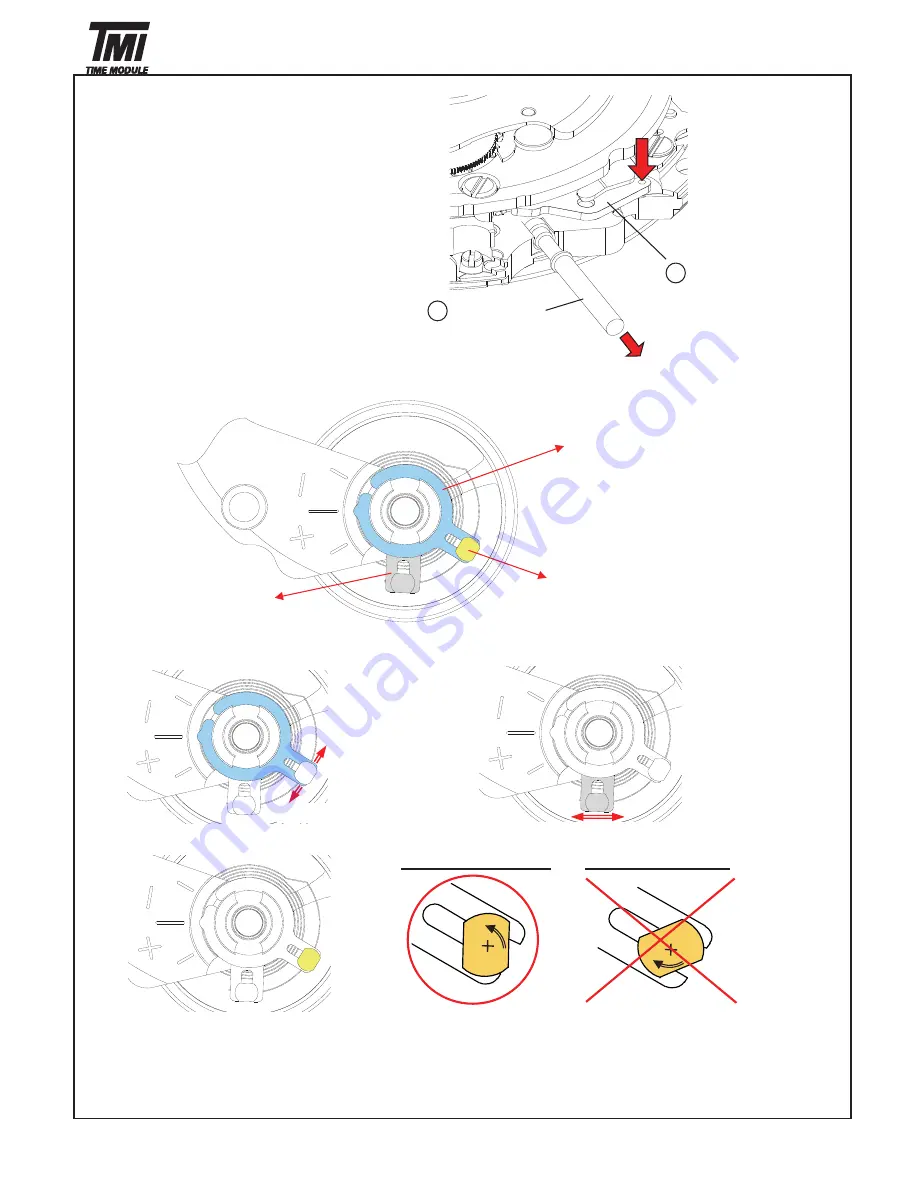

8.To remove the winding stem

1) Set the winding stem to normal position.

2) Pull out the winding stem, while pushing "A"

Setting lever

Winding stem

9.Accuracy adjustment

Regulator

Regulator pin

Stud support

Note:

䞉

䞉

Regulator … Time adjustment

䞉

䞉

Stud support … Beat error adjustment

䞉

䞉

Regulator pin … Gap adjustment of balance spring and regulator pin

12

Version-02

Cal.NE20C

Anticlockwise rotation

No clockwise rotation

TECHNICAL GUIDE

56

54

SII Products

(+) side

(-) side

A