Version-01

Cal.VK68A

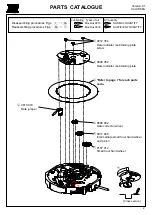

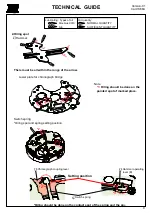

5.To remove the winding stem

1) Set the winding stem to normal position.

2) Pull out the winding stem while pushing "A".

Push "A"

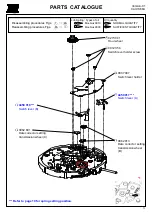

6.To remove or install the battery

1) Remove the hook of the switch spring's battery clamp.

Switch spring

Battery clamp

1) When Removing

Main plate

2) When Installing

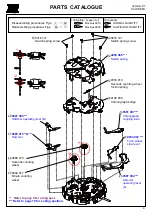

7.Remarks on installing the battery

1) After the battery is replaced with a new one, or after the

battery is reinstalled following the repairing procedures,

be sure to touch the AC terminal of circuit block and

the switch spring with conductive tweezers to reset

Tweezers

the circuit as illustrated.

TECHNICAL GUIDE

11

2) Insert the battery sideways, and have the hook of the switch spring's battery clamp catch the

main plate.

○

16