Chapter 2

INSTALLATION AND CONNECTION

2-7

1.3. Removable Terminal Plug Connection

Solid cable and stranded cable

Shielded cable

7 mm*

2

7 mm*

2

20 mm

(0.28")

(0.28")

(0.79")

*

2

Expose 8 mm

0.31 or more hen using

the above ferrule terminal, and cut off an

e tra conductor protruding from the slee e.

Note

A oid soldering stranded or shielded cable,

as contact resistance may increase when

the cable is tightened and the solder is

crushed, possibly resulting in an e cessi e

rise in joint temperatures.

•

Cable sheath to trim

Step 1.

iring the supplied remo able terminal plug.

1-1.

Loosen the terminal screws to insert the wire.

1-2.

Tighten the terminal scre s.

nsure that the ire does not break free hen

pulled. If the wire does pull free, repeat the

connection procedure from the start.

Step 2.

nsert the ired terminal plug into the corresponding

terminal block in the unit s rear panel.

Step 3.

Tighten the ing scre

po er input terminal

only .

Notes

• o not re erse Steps 1 and abo e. oor contact may

result if force is applied to the unit s internal circuit board

pins hile the terminal scre s are being tightened.

• hen detaching the terminal plug, pull it straight out.

ulling it out at an angle may cause the terminal plug or

terminal block to break.

Fixing screw

Terminal screw

Removable terminal

plug (accessory)

Tightens

Loosens

1

2

3

Slotted screwdriver

[Recommended type of screwdriver ]

Blade width*

1

*

1

For DC power input terminal: About 3.5 mm (0.14")

For other terminals: About 2.5 mm (0.1")

10

9

CONTR

OL INPUT

1

CONTR

OL OUTPUT

24V 200mA

LAN

AC AD

APTER

DC INPUT

24V 200mA

DC INPUT

1

GND

SIGNAL

Tips

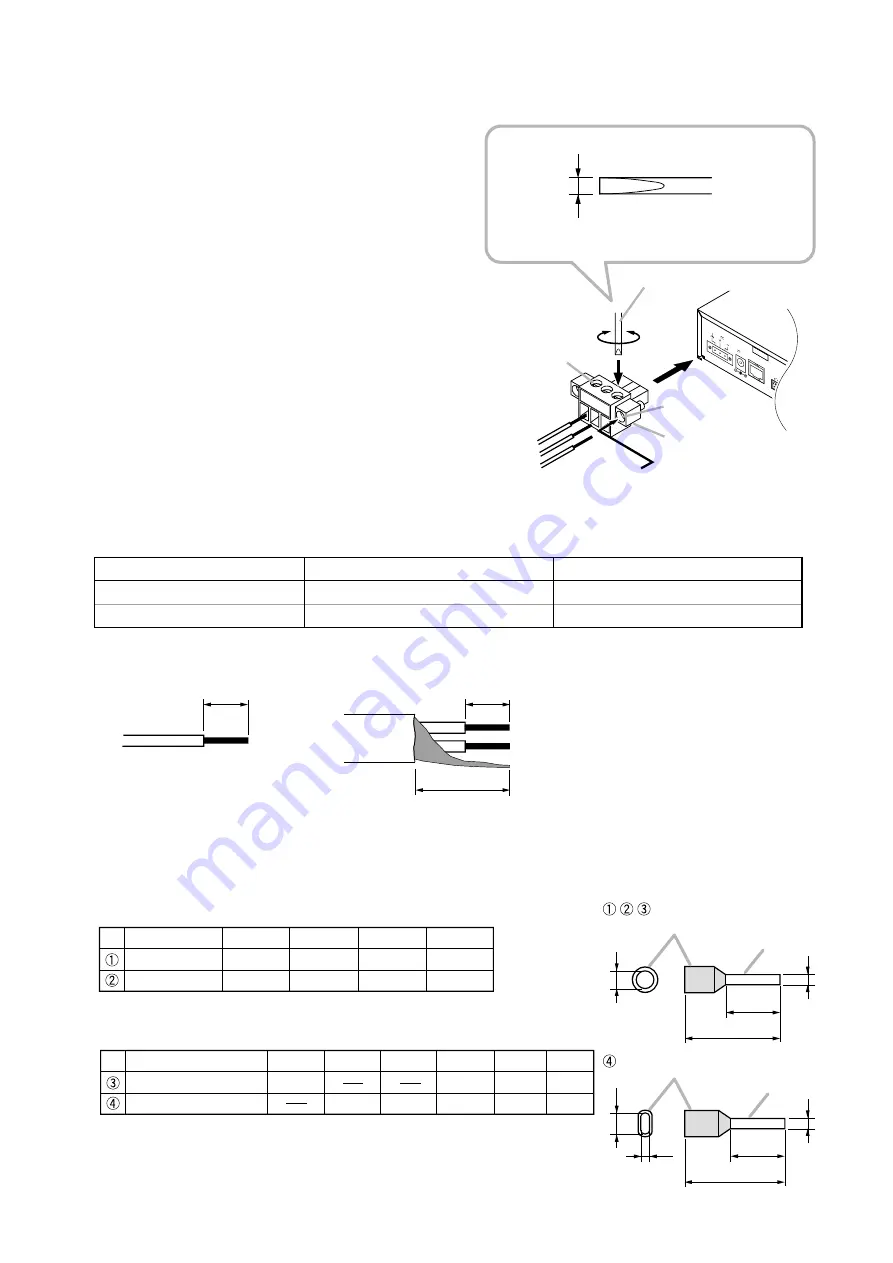

• Applicable cable si e

For DC power input terminal

For other terminals

Conductor cross-section area

0. . mm

2

0.1 1. mm

2

A

A

1 or e ui alent

A

1 or e ui alent

• hen connecting cables or a shielded cable to a single terminal, use a ferrule terminal ith an insulation

sleeve to crimp the cables because such cable conductors could become loose.

1 ecommended ferrule terminals for cables other than po er supply cables

made by hoeni ontact

ecommended ferrule terminals for po er supply cables

made by hoeni ontact

rimping tool

OX 10S made by hoeni ontact

Insulation sleeve

Contact section

Insulation sleeve

Contact section

a

l

2

a

1

a

2

l

1

l

2

l

1

b

b

Model Number

a

1

l

1

l

2

AI 1,5-8 BK

AI-TWIN 2 x 1,5-8 BK

6.6 (0.26)

a

2

3.6 (0.14)

14 (0.55)

16 (0.63)

2.3 (0.09)

8 (0.31)

8 (0.31)

a

3.4 (0.13)

Unit: mm (in)

b

1.8 (0.07)

Model Number

a

l

1

l

2

AI 0,34-8 TQ

AI 0,5-8 WH

2 (0.08)

Unit: mm (in)

2.5 (0.1)

12.5 (0.49)

14 (0.55)

8 (0.31)

8 (0.31)

b

0.8 (0.03)

1.1 (0.04)

Summary of Contents for NX-300

Page 7: ...Chapter 1 SYSTEM SUMMARY ...

Page 12: ...Chapter 2 INSTALLATION AND CONNECTION ...

Page 23: ...Chapter 3 SYSTEM SETTINGS NX 300 SETTING SOFTWARE ...

Page 113: ...Chapter 4 SETTINGS AND MANAGEMENT BY BROWSER ...

Page 140: ...Chapter 5 SETTINGS NECESSARY WHEN USING THE NX 300 OPERATION SOFTWARE ...

Page 163: ...Chapter 6 APPENDIX ...