Model: TTT-710

8.6 Electrode Arm Maintenance and Inspection

- 97 -

•

If there is deviation in the left-to-right direction, go to step

②

and if there is deviation in the

front-to-back direction, go to step

③

.

②

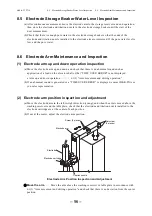

Adjust the left-to-right direction position.

⋅⋅⋅⋅⋅⋅

Using a hexagonal wrench (2mm), loosen the

arm rear and left side set screws (2 places) and free fixing of the arm in the left-to-right direction.

Next, after adjusting the arm in the left-to-right (swing) direction so that the electrode arm is at the

center position, fix the arm by retightening the set screws (2 places) with the hexagonal wrench as

they were originally.

③

Adjust the front-to-back direction position.

⋅⋅⋅⋅⋅⋅

Using a hexagonal wrench (2mm), loosen

the arm upper screws (2 places) and free fixing of the arm front-to-back direction. Next, after

adjusting the arm by blocks in the front-to-back direction so that the electrode arm is at the center

position, retighten the set screws (2 places) with the hexagonal wrench as they were originally.

④

Return the arm to its original state.

⋅⋅⋅⋅⋅⋅

Return the arm to its original position in accordance

with 6.1(1) “Arm movement and stirring operation”.

Summary of Contents for TTT-710

Page 115: ... 114 ...

Page 117: ... 116 ...