Summary of Contents for 2 Stroke 5BS

Page 1: ...OWNER S WAND E3 00...

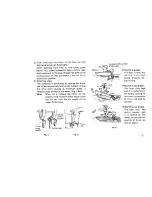

Page 5: ...MAIN PARTS...

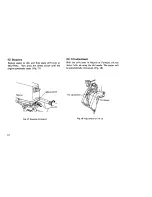

Page 28: ...2 AVAILABLE PROPELLER wavy duty Size Blade x Dia x Pitch mm 1 26...

Page 29: ...VI WIRING DIAGRAM n II _ _ ExtenEion cord m 27...

Page 30: ......

Page 31: ......

Page 32: ...v TOHATSU CORPORATION i Apr 93 Pmted in Japan 3...