1-3-2

T6600STA

1.2. Standard solder

e. Soldering Iron

Use a pencil-type soldering iron (less than 30

watts).

f. Solder

Eutectic solder (Tin 63%, Lead 37%) is recom-

mended.

g. Soldering time

Do not apply heat for more than 4 seconds.

h. Preheating

Leadless capacitor must be preheated before

installation. (130°C~150°C, for about two minutes.)

Notes:

a. Leadless components must not be reused after

removal.

b. Excessive mechanical stress and rubbing for the

component electrode must be avoided.

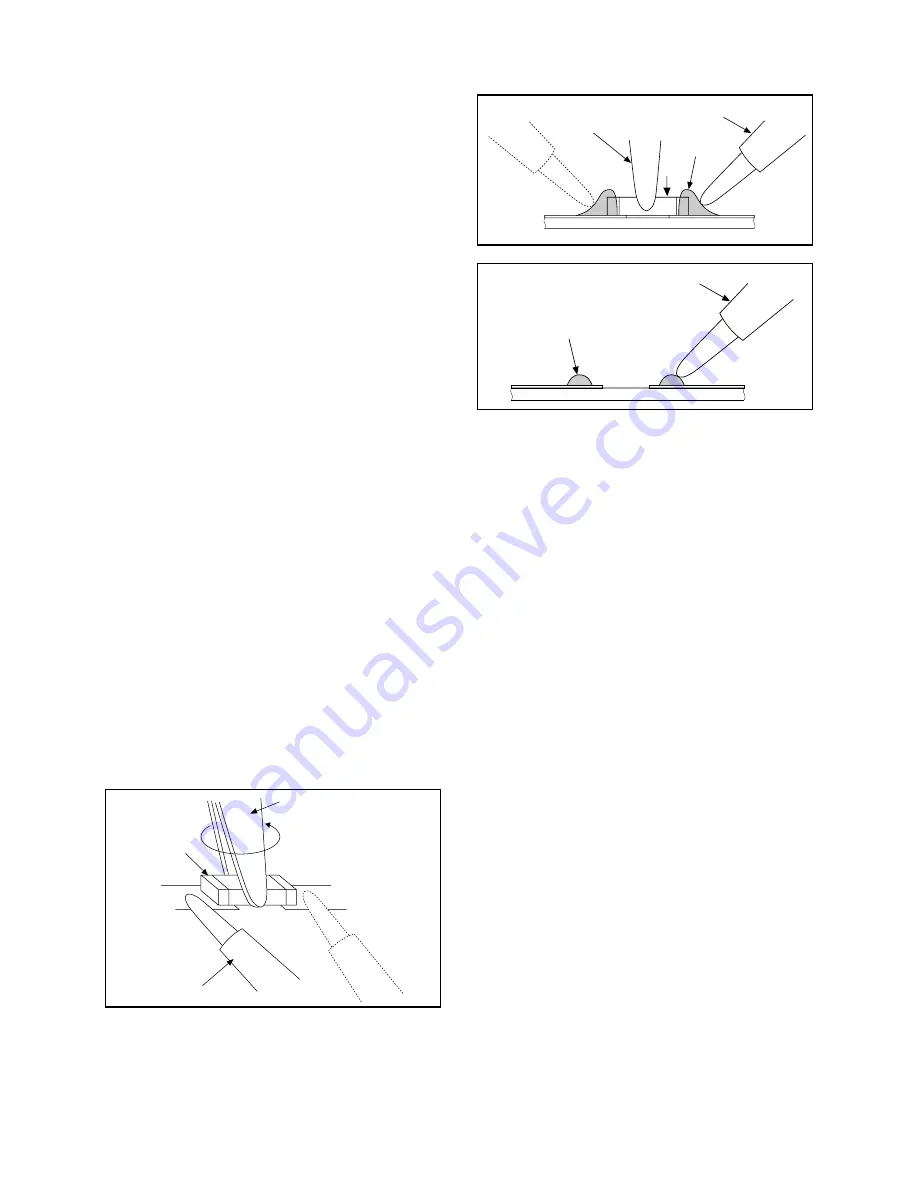

2. Removing the leadless component

Grasp the leadless component body with tweezers

and alternately apply heat to both electrodes. When

the solder on both electrodes has melted, remove

leadless component with a twisting motion.

Notes:

a. Do not attempt to lift the component off the board

until the component is completely disconnected

from the board by the twisting action.

b. Take care not to break the copper foil on the printed

board

3. Installing the leadless component

a. Presolder the contact points of the circuit board.

b. Press the part downward with tweezers and solder

both electrodes as shown below.

Note:

Do not glue the replacement leadless component to

the circuit board.

How to Remove / Install Flat Pack IC

Caution:

1.

The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering ma-

chine, whose shape matches that of the Flat Pack-

IC.

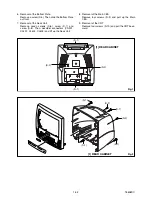

2. Do not apply the hot air to the chip parts around the

Flat Pack-IC for over 6 seconds as damage may

occur to the chip parts. Put Masking Tape around

the Flat Pack-IC to protect other parts from dam-

age. (Fig. S-1-2)

3. The Flat Pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or solder lands under the IC when removing it.

1. Removal

With Hot - Air Flat Pack - IC Desoldering Machine:

a. Prepare the Hot - Air Flat Pack - IC Desoldering

Machine, then apply hot air to Flat Pack - IC (about

5~6 seconds). (Fig. S-1-1)

b. Remove the Flat Pack- IC with tweezers while

applying the hot air.

With Soldering Iron:

a. Using desoldering braid, remove the solder from all

pins of the Flat Pack - IC. When you use solder flux

which is applied to all pins of the Flat Pack - IC, you

can remove it easily. (Fig. S-1-3)

b. Lift each lead of the Flat Pack - IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air Desoldering

Machine. (Fig. S-1-4)

With Iron Wire:

a. Using desoldering braid, remove the solder from all

pins of the Flat Pack - IC. When you use solder flux

which is applied to all pins of the Flat Pack - IC, you

can remove it easily. (Fig. S-1-3)

Chip

Tweezers

Soldering Iron

Soldering Iron

Tweezers

Solder

Soldering Iron

Presolder

Summary of Contents for LT-VHS-36

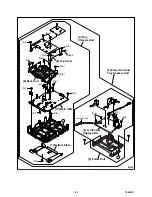

Page 17: ...1 5 4 T6608DC Fig 4 S 10 S 10 S 10 S 10 Anode Cap 11 CRT CRT CBA...

Page 36: ...Main 1 5 Schematic Diagram 1 8 3 1 8 4 T6608SCM1...

Page 37: ...Main 2 5 Schematic Diagram 1 8 5 1 8 6 T6608SCM2...

Page 38: ...Main 3 5 Schematic Diagram 1 8 7 1 8 8 T6608SCM3...

Page 39: ...Main 4 5 Schematic Diagram 1 8 9 1 8 10 T6608SCM4...

Page 40: ...1 8 11 1 8 12 T6608SCM5 Main 5 5 Schematic Diagram...

Page 42: ...1 8 15 1 8 16 H V Power Supply 2 2 Schematic Diagram T6608SCP2...

Page 43: ...1 8 17 1 8 18 T6608SCCRT CRT Schematic Diagram...

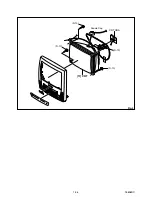

Page 58: ...1 14 3 T6608PEX Packing S3 S6 X3 S2 X1 TAPE S1 FRONT S4 X2 1 X2 2 X2 6...

Page 91: ...2 4 9 Z13PDA Fig DM16 43 41 42 L 13 Fig DM17 44 45 Slide P 9...

Page 98: ...LT VHS 36 T6608FJ 2004 06 03...