17

3.

Check for loose bolts, rust, paint removal or other damaged areas. If any of these

problems are seen, repairs should be performed immediately.

★

ANNUAL INSPECTION

1.

The Air Winch should be dis-assemblied and inspected once a year. (For details

contact your dealer or distributor.)

2.

For repairs, contact your dealer or distributor.

★

STORAGE

1.

Remove all debris or dirt from the Air Winch.

2.

After using the Air Winch in order to prevent rust build up, apply about 50 cc of

lubricating oil into the inlet of the Air Winch and operate for about 5 seconds.

3.

To prevent dirt or debris from entering the inlet of the Air Winch, apply a plug before

storage.

4.

To prevent rust, store the hoist in a dry place.

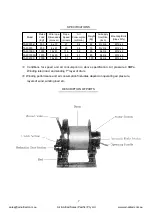

TROUBLE SHOOTING

△

!

WARNING

; If the Air Winch needs to be dis-assembled and repaired, please bring

the Air Winch to a service shop or the dealer.

ITEM

CAUSE

COUNTERMEASURE

Not enough power * Not enough air pressure

* Check air supply

to wind

* Friction in air hose

* Select new size hose

* Vane wear

* Replace parts

* Not enough lubrication

* Check exhaust for lubrication

* Brake is not open fully

* Check air pressure, air leakage

or rust.

Does not operate

* Foreign matter in motor

* Dis-assemble and clean

* Brake is not open fully

* Replace brake piston o-ring

* Brake release hole is plugged

* Rust in automatic brake

* Dis-assemble and repair

* No air supply

* Bent hose and check valve

Air is leaking

* Breakage of o-ring, packings * Replace parts

sales@air-allied.com.au

Air & Allied Sales (Pacific) Pty Ltd

www.air-allied.com.au