7

1.2

SAFETY DEVICES INSTALLED ON THE MACHINE

1.2.1

MECHANICAL SAFETY DEVICES

As regards safety devices of a mechanical nature, the slicing machine

described in this manual complies with the Machinery Directive

2006/42/EC

and the EN 1974 standard

(Slicing machines, safety and hygiene

requirements), which envisages the following (see 1.3.3):

-

removable blade guard

-

irremovable fixed blade guard ring around the blade to protect the area

not used during cutting

-

product pusher that cannot be completely overturned

-

product pusher knob

-

hand guard made of transparent plastic secured to the product holder tray

-

carriage that can only be removed when the slice thickness control dial

and the ribbed thickness gauge tray is set to “0” and when the carriage is

positioned at the start of the run at the operator side. In these conditions,

the mechanical lock intervenes and it is possible to remove the product

holder tray.

N.B:

In accordance with paragraph 1.7.2 “Warning of residual risks” of

Annex 1 of the Machinery Directive 2006/42/EC, it should be noted

that the blade guard ring, in the sharpening area, does not totally

eliminate the risk of being cut. While reducing the extent of the risk,

the ring is made in compliance with European Standard EN 1974.

1.2.2

ELECTRICAL SAFETY DEVICES

Safety devices to protect against electrical hazards have been added in accordance

with:

−

EN 60335-1

standards

−

EN 60335-2-64

standards

−

the Low Voltage Directive

2014/35/UE

−

the Electromagnetic Compatibility Directive

2014/30/UE

A relay is inserted in the control circuit and, in the event of an accidental

power cut, requires the slicing machine to be restarted (reset) intentionally.

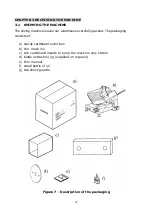

Summary of Contents for CROMATIC 250

Page 30: ...30 ...

Page 31: ...1 EN User Guide TOMAGA CHROMATIC SEVENTIES INSTRUMENT ELECTRICAL SLICER Models 250 300 350 ...

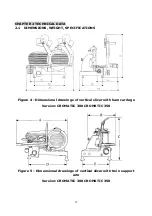

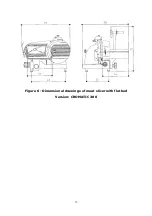

Page 43: ...13 Figure 6 Dimensional drawings of meat slicer with flat bed Version CROMATIC 300 ...

Page 62: ...32 ...

Page 97: ...35 ...

Page 98: ...36 ...