17

18

5.2 Transportation

1. Shutdown engine for transportation

2. For transportation, tighten fuel tank cap securely and close fuel cock to prevent fuel from

spilling.

3. Drain fuel for transportation over long distances or poor roads.

4. Secure machine firmly to prevent it from moving or tipping.

5. The rammer should be transported in the same position as if it is placed on level ground.

In case the rammer must be laid down for transportation, drain the fuel tank as wellas the

carburetor and make sure that the oil plug is tightened securely, then tie the rammer to the

vehicle at points (a) and (b).

6. The rammer must be laid down so that the air filter faces up. After laying the rammer

down, make sure that there is no leak from the fuel from cap (c).

7. Make sure lifting device has enough capacity to hold machine (see identification plate on

machine for weight). Use central lifting point (a) when lifting machine.

8. Use trolley kit (not included) for short distance transportation.

Visit www.tomahawk-power.com for wheel kit accessories and more.

5.3 Spark Plug

Check and clean spark plugs regularly. A fouled, dirty spark plug may cause hard starting

and poor engine performance. Set spark plug gap to recommended clearance. Refer to

engine manual.

NOTICE: A loose spark plug can become very hot and may cause engine damage.

The muffler and engine cylinder become very hot during operation and remain

hot for a while after stopping the engine. Allow engine to cool before removing

spark plug.

WARNING

Summary of Contents for TR68H

Page 2: ...2 ...

Page 9: ...9 3 Labeling 3 1 Label Locations ...

Page 13: ...13 ...

Page 23: ...7 Equipment Size 23 ...

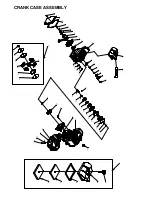

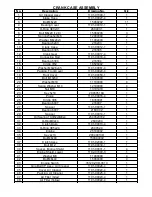

Page 29: ...TR68H VIBRATORY RAMMER Operations Manual 29 ...

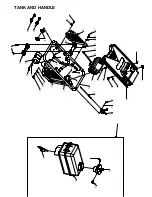

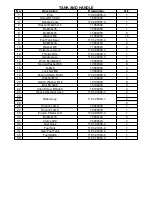

Page 30: ... TANK AND HANDLE 17 ...

Page 32: ... CRANK CASE ASSEMBLY ...