TOMARK, s.r.o.

Airplane Maintenance Manual

Chapter 05 Inspection and Maintenance

Page 46

Issue: 04.APR 2016

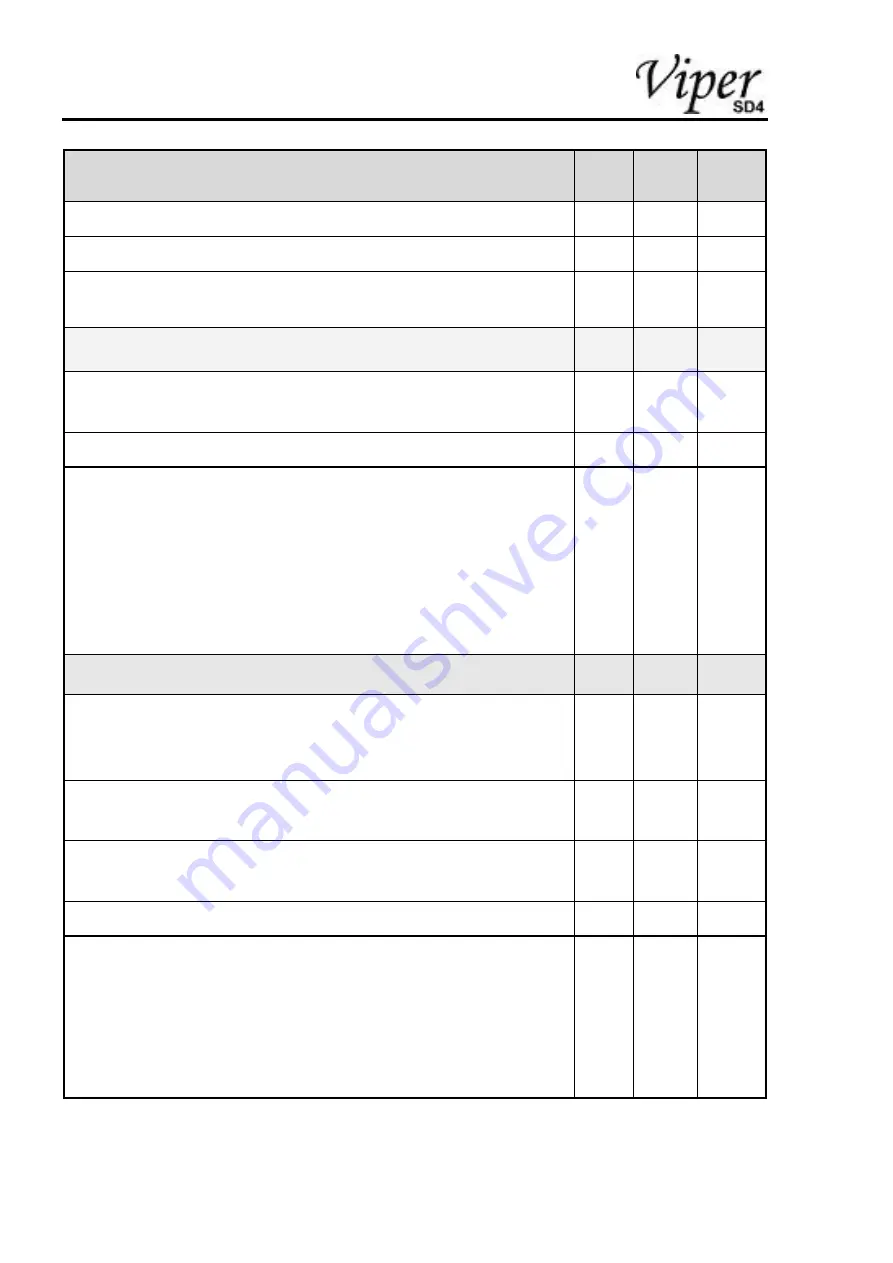

Scheduled Inspection

(50 h)

100 h/

annual

as

specified

Check fuel cap for condition and proper operation.

○

Drain fuel at fuel tank bottom.

○

Remove drain valve and inspect for sediment

200h/

2 Years

Fuel Lines, Hoses and Elements

Inspect fuel lines and hoses for damage, leakage and proper

routing.

○

Visually inspect fuel selector valve for leakage.

○

○

When refilling system after complete drain (aircraft in level

attitude):

Check indication and low level warning operation.

Indicator must not start indication of usable fuel when total

fuel quantity in system is below published unusable quantity

of 5 Liter per side. Low level warning must trigger at steady

quantity of 10 Liter per side.

500h/

5 years

Instruments

Check instruments for condition, security and proper

markings. (Instrument dials or markings may not be

excessively faded out due to sunlight.)

○

Check instrument lines and wiring for condition, proper

routing, and security.

○

Check Pitot-static system for condition, proper installation

and security.

○

Check Pitot-static system moisture traps, clean as required.

○

Perform Pitot-static system leak test:

Pitot: pressurize to 100 KIAS, allowable drop 5 knots/min

Static: evacuate to 1000 ft., allowable drop 100 ft./min.

Note: allow vertical speed indicator (on EFIS) to stabilize

before taking measurement. Most likely points of leakage are

the instruments themselves and hose connections.

200h/

2 Years