TOMARK, s.r.o.

Airplane Maintenance Manual

Chapter20 Standard Practices-Airframe

Issue: Issue: 11.AUG 2016

Page 89

NOTE

For cleaning and degreasing:

▶

Use a clean paper towel or cloth. After wiping, the towel or cloth must

not show any contamination.

▶

For perfect degreasing the whole surface, clean always smaller part of

surface, after its perfect cleaning continue on.

▶

Cleaning liquid always apply on the cloth only and wipe it off from the

surface before its evaporating.

NOTE

The surfaces that are to be connected must be dry.

▶

Clean before application of bonding sealant.

▶

Apply bonding sealant on one of the surfaces (applies to fuel tank

only), which should be sealed together.

▶

Apply the adhesive directly from the packing by means of the

extrusion gun, plastic spatula or paintbrush in such a way that the

layer of sealant is equally thick and integral, without bubbles or

uncovered areas. The optimum thickness of the applied coat is 0.25

mm (0.01 in).

▶

After applying bonding sealant connect both parts together, fix them

by clecos and rivet them.

NOTE

After proper riveting the continual bur of adhesive is created on the

edge of connected surfaces. If this bur is big, it is possible to wipe it

off with the plastic spatula and finally with cloth dipped in degreasing

agent.

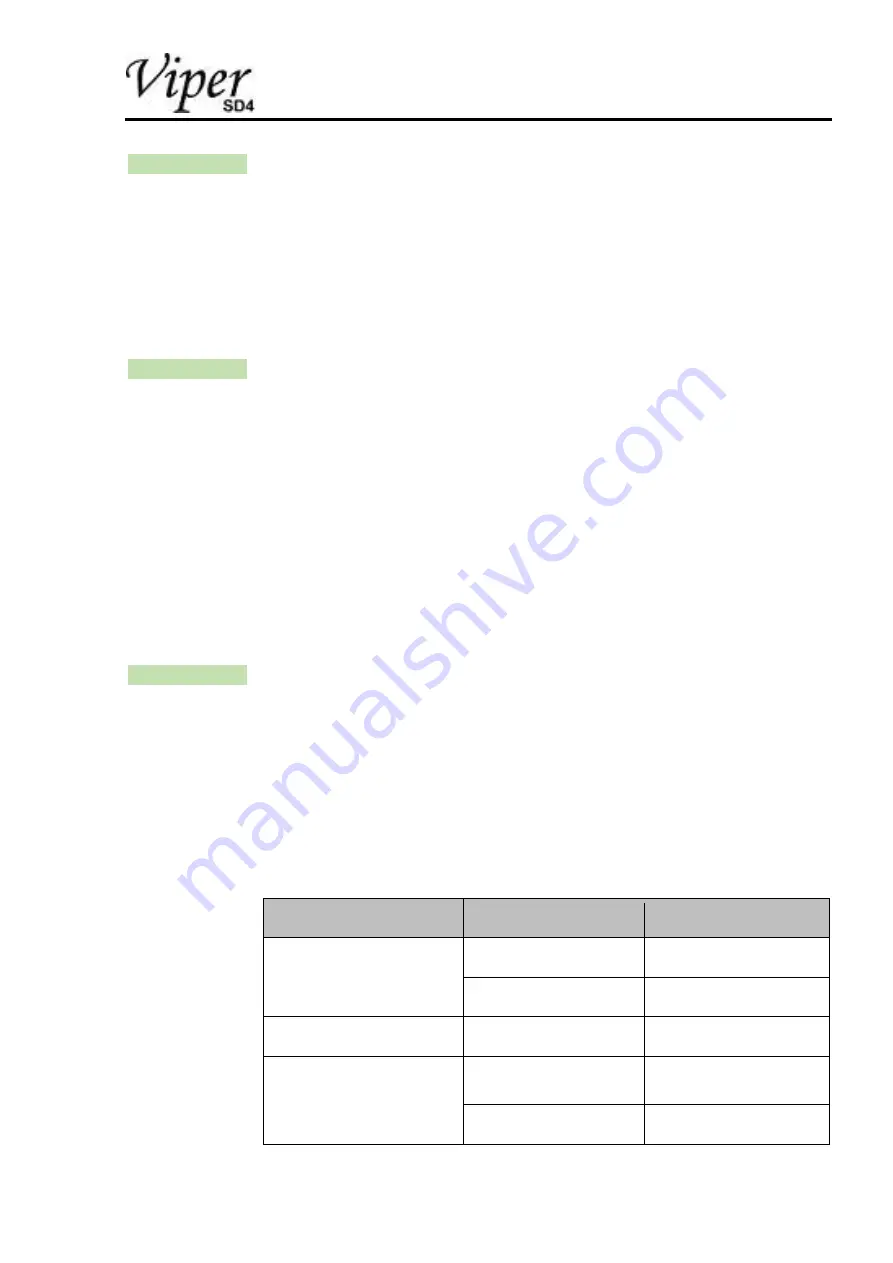

20-10-03 Hoses and Tubes

The hoses and tubes used on the Viper SD-4 RTC are connected in

different ways as presented in the following table:

System

Line type

Connection type

Fuel (firewall forward) Hose

Hose clamps

Fire sleeves

Fire protection tape

Fuel (aft of firewall)

Tube (aluminium)

Fittings

Oil

Hoses

Hose clamps

(Rotax or worm drive)

Fire sleeves

Fire protection tape