Battery and Charger

MERGE 11-26

Chapter 11

Operation

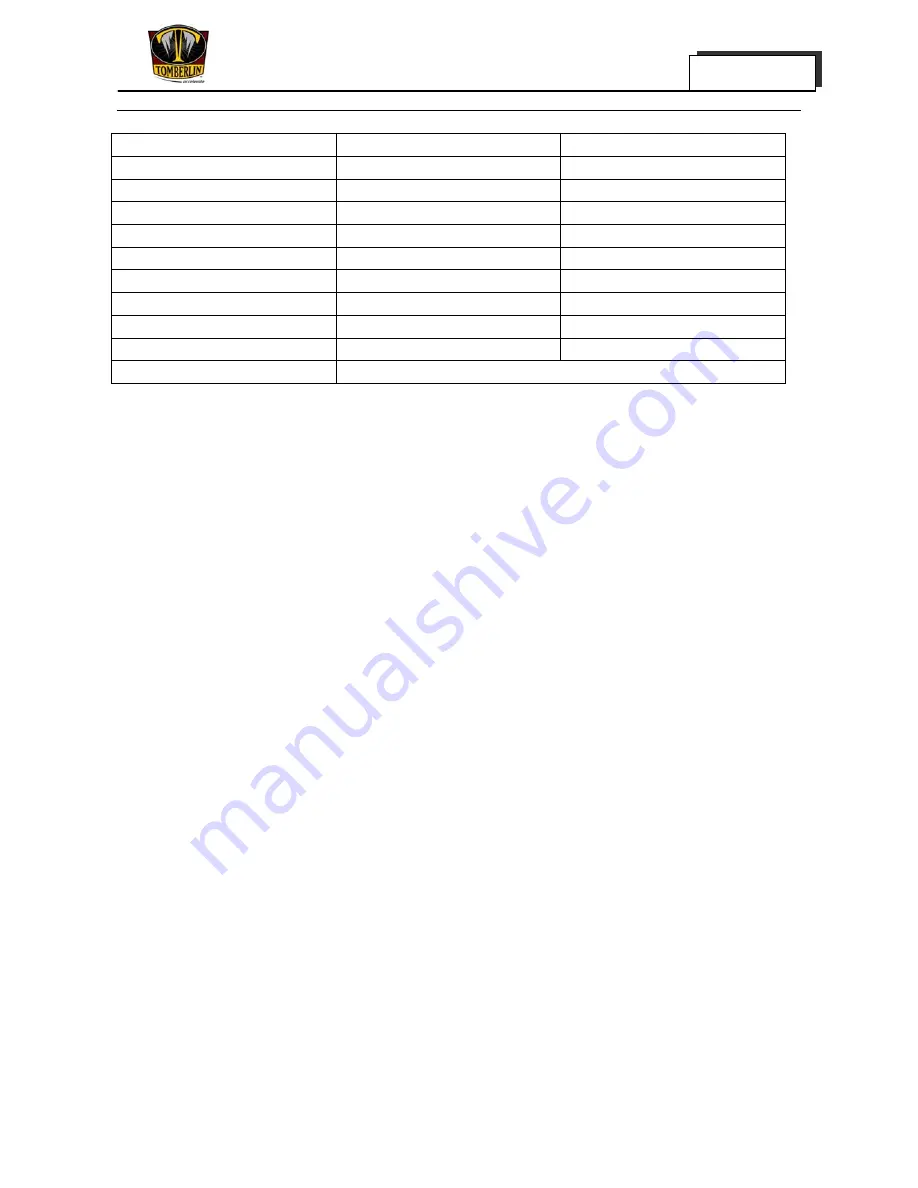

Charger Model:912-

Xx0x(10 LED)

Xx1x(1 LED)

AC ON

Solid YELLOW

LED Active

AC Low

Flash YELLOW

Flash YELLOW

Thermal Cutback

Flash Bar graph

Flash YELLOW

<80% Charge Indicator

-

Short Flash GREEN

>80% Charge Indicator

Solid YELLOW

Long Flash GREEN

100% Charge Indicator

Solid GREEN

Solid GREEN

Fault Indicator

Flash RED

Flash RED

DC Ammeter

LED Bargraph

-

Bat Temp Compensation

Automatid

Optional

Maintenance Mode

Auto-restart if V<2.1Vpc or 30 days elapse

Installation Instructions

WARNING

:

The output of chargers with greater than 48V may pose an energy and/or shock hazard under

normal use. These units must be installed in the host equipment in such a manner that the

output cable and battery connections are only accessible with the use of a tool by qualified

personnel.

1) Determine Mounting location:

While its sealed nature allows the charger to be mounted virtually anywhere, the choice of

mounting location and orientation is extremely important. For optimum performance and shortest

charge times, mount the charger in an area with adequate ventilation. The charger should also be

mounted in an area that will be relatively free of oil, dirt, mud, or dust since accumulations within

the fins of the charger will reduce their heat-dissipating qualities. Optimal cooling also occurs when

the charger is mounted on a horizontal surface with the fins vertical. More airflow from below the

charger will help cool the fins, so mounting above open areas or areas with cut-outs for airflow is

desirable. Contact Delta-Q for information on other mounting orientations. As the charger may get

hot I operation, the charger must be installed such that risk of contact by people is reduced. The

charger’s AC plug must be located at least 18’’ above the floor/ground surface and the status

display must be visible to the user.

2) Mounting Procedure:

Mount the charger by the mounting plate using appropriate fasteners (i.e.1/4’’ or M6 with locking

hardware).For UL2202 compliance, a 12 AWG green bonding wire with ring terminals must be

attached from the bonding stud located on the front of the charger (identified by) to the vehicle

frame. The vehicle connection must be made using corrosion resistant hardware (e.g., a #

10stainless steel machine screw with at least two threads of engagement and, if required, a paint

piercing washer).

3) DC Battery Connection Procedure:

a) The green wire outputs battery voltage when the charger is not plugged into AC to provide an

interlock function—see fig.1. If used, a user-supplied 1 A fast-blow external fuse must be

installed inline to prevent damage. Shorting or drawing more than 1 A may damage charger and

Summary of Contents for 2010 E-Merge

Page 2: ......

Page 79: ...Electric Component MERGE 9 7 Chapter 9 Control circuit ...