PACKAGE CONTENTS

4

A. ELECTRIC MOTOR:

The motor is used to power the pump. It contains a thermal overload protector. If

the motor overheats for any reason, the thermal overload protector will shut it down in order to prevent

the motor from being damaged.

AIR COMPRESSOR PUMP:

The pump is used to compress the air and discharge it into the tank via

the piston moving up and down in the cylinder.

B. AIR TANK:

The tank is used to store the compressed air.

C. TANK PRESSURE GAUGE:

The gauge is used to measure the stored air pressure level of the tank. It

is not adjustable by the operator and does not indicate line pressure.

D. AIR PRESSURE REGULATOR:

The regulator is used to adjust line pressure to the tool you are using.

Turn the knob clockwise to increase pressure and counterclockwise to decrease pressure.

Never exceed the maximum working pressure of the tool.

E. REGULATED PRESSURE GAUGE:

The gauge is used to measure the regulated outlet pressure.

F. AIR LINE OUTLET:

The outlet is used to connect 1/4 in. NPT air hose.

G. AIR TANK DRAIN VALVE:

The drain valve is used to remove moisture from the air tank after the unit is

shut off.

WARNING:

WARNING:

Never attempt to open the drain valve when the tank pressure is more than 10 PSI.

H. PRESSURE RELIEF VALVE:

The valve is used to prevent system failures by relieving pressure from

the system. If the pressure reaches the preset level and the pressure switch will not shut down the

motor, it will automatically pop open. You can also pull the ring on the valve to open.

I. ON/OFF SWITCH:

This switch turns on the compressor and is operated manually. When in the ON

position, it allows the compressor to start up or shut down automatically, without warning, upon air

demand. ALWAYS set this switch to OFF when the compressor is not being used and before

unplugging the compressor.

J. POWER CORD:

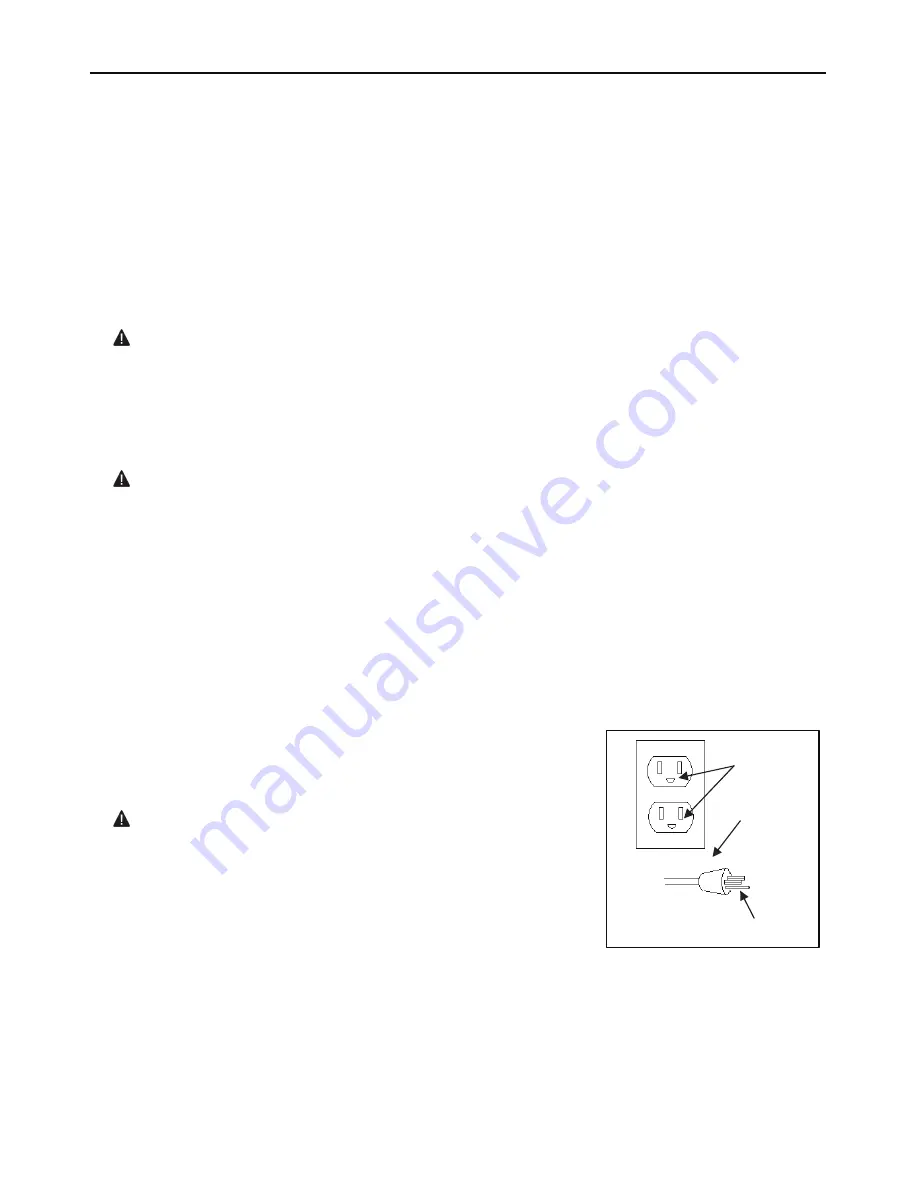

This product is for use on a nominal 120-volt circuit and should be grounded. A cord

with a grounding plug as illustrated must be used. Make sure that the product is connected to an outlet

that has the same configuration as the plug (see Figure 1). No adapter should be used with this product.

Check with a licensed electrician if the grounding instructions are

not understood or there is doubt as to whether the product is properly

grounded. Do not modify the plug provided. If it will not fit the outlet,

have the proper outlet installed by a licensed electrician.

DANGER

:

:

Improper installation of the grounding plug will result

in a risk of electric shock. If repair or replacement of the cord or plug

is necessary, do not connect the grounding wire to either flat blade

terminal. The grounding wire is in the green outer surface.

Grounded

outlet

Grounding Pin

Plug

Figure 1