11

INSTALLING THE DUST BAG ASSEMBLY

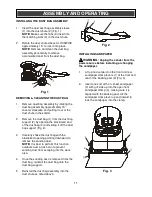

1. Insert the dust duct bag assembly sleeve

(1) into the dust chute (2) (Fig. 1).

NOTE: Make sure the tabs (3) insert into

the matching slots (4) in the dust chute.

2. Rotate the dust chute sleeve CLOCKWISE

approximately 15° to lock it into place.

NOTE: Remove and clean the dust bag

assembly periodically to remove

accumulated dust from the dust bag.

REMOVING & CLEANING THE DUST BAG

1. Remove dust bag assembly by rotating the

dust bag assembly approximately 15°

counter clockwise and pulling it out of the

dust chute in the sander.

2. Remove the dust bag (1) from the dust bag

support (2) by opening the elasticized end

of the dust bag (3) and sliding it off the dust

bag support (Fig. 2).

3. Carefully shake the dust bag with the

elasticized opening pointing downward to

remove the sanding dust.

NOTE: It is best to perform this function

outdoors over a trash can to prevent

sanding dust from escaping into the work

area.

4. Once the sanding dust is removed from the

dust bag, reinstall the dust bag onto the

dust bag support.

5. Reinstall the dust bag assembly into the

dust chute as noted above.

INSTALLING SANDPAPER

WARNING:

Unplug the sander from the

power source before installing or changing

the sandpaper.

1. Lift up and outward on the front and rear

sandpaper clamp levers (1) at the front and

rear of the backing pad (2) (Fig. 3).

2. Insert one end of the ¼ sheet sandpaper

(3) with grit side up into the open front

sandpaper clamp (4), making sure it is

aligned with the backing pad. Lift the

sandpaper clamp lever up and inward to

lock the sandpaper into the clamp.

ASSEMBLY AND OPERATING

!

Fig. 1

Fig. 2

Fig. 3

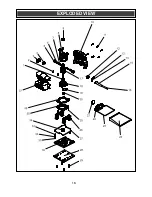

Summary of Contents for 241-9946

Page 16: ...EXPLODED VIEW 16...