12

INSTALLING SANDPAPER – cont’d

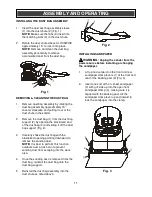

3. Wrap the sandpaper sheet (3) over the

backing pad (2) and insert it into the open

rear sandpaper clamp (5) (Fig. 4).

NOTE: Make sure the sandpaper is pulled

tight over the backing pad for proper

sanding operation.

4. Lift the sandpaper clamp lever up and

inward to lock the sandpaper into the

clamp.

PUNCHING HOLES IN SANDPAPER

The sandpaper must have 8 holes punched in it

to allow the sanding dust to escape from the

working surface. The pattern of these holes

must match the hole pattern on the sanding pad.

If the sandpaper you are using does not have

the holes punched, use the hole punch supplied

with the tool to pierce the sandpaper in the

correct locations.

1. Install the sandpaper as shown in

Fig. 3 & 4.

2. Place the hole punch (1) on a sturdy flat

surface (Fig. 5).

3. Align the corner of the sanding pad (2) with

the corner of the hole punch (3). This will

ensure the holes are punched in the

correct location.

4. When the sanding pad is correctly aligned

on the hole punch, press the sanding pad

firmly onto the hole punch.

NOTE: The sharp pegs (4) in the hole

punch will pierce the sandpaper in the

correct location.

SANDPAPER SELECTION

Selecting the correct grit and type of sandpaper

is extremely important in achieving a high

quality sanded finish. Aluminum oxide, silicon

carbide and other synthetic abrasives are best

for power sanding. Natural abrasives such as

flint and garnet are too soft for economical

use in power sanding.

In general, coarse grit will remove the most

material and finer grit will produce the best finish

in all sanding operations. The condition of the

surface to be sanded will determine which grit

will do the best job. If the surface is rough, start

with a coarse grit and sand until the surface is

uniform. Medium grit may then be used to

remove scratches left by the coarser grit. Fine

grit should be used for finishing the surface.

Always continue sanding with each grit until the

surface is uniform.

ASSEMBLY AND OPERATING

Fig. 4

Fig. 5

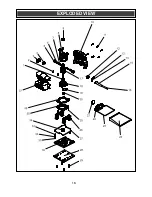

Summary of Contents for 241-9946

Page 16: ...EXPLODED VIEW 16...