13

WARNING:

Always wear safety goggles

or safety glasses with side shields when

operating your sander. Failure to do so could

result in foreign objects being thrown into

your eyes resulting in possible serious eye

damage.

Always wear an appropriate dust mask and

hearing protection when using your sander.

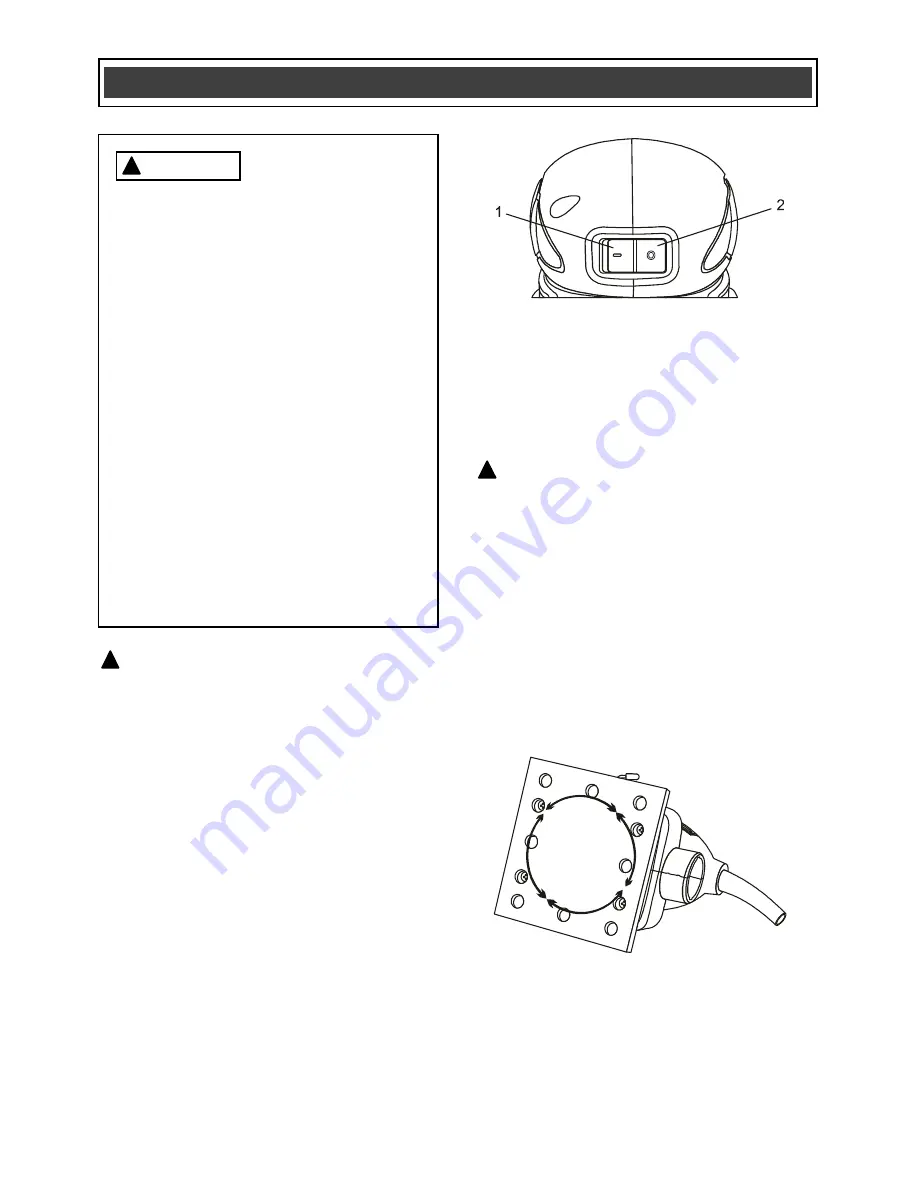

ON/OFF SWITCH

To turn the switch ON, press the right hand side

of the ON/OFF switch (1) (Fig. 6). To turn the

switch OFF, press the left hand side of the

ON/OFF switch (2).

SANDING

Clamp or otherwise secure your workpiece to

prevent it from moving under the sander while

being sanded.

WARNING: An unsecured workpiece

could be thrown toward the operator causing

injury.

Place the sander on the workpiece so that the

complete sandpaper surface is in contact with

the workpiece. Turn the sander ON by pressing

on the side of the ON/OFF switch. Move the

sander slowly over workpiece making

successive passes in parallel lines, circles or

crosswise movements. Because the orbital

motion of the sanding pad moves in tiny circles,

it is not necessary to move the sander with the

grain or in the same direction for successive

passes (Fig. 7).

!

For safety reasons, the operator must

read the sections of this Owner’s

Manual entitled "GENERAL SAFETY

WARNINGS", "POWER TOOL SAFETY",

"SPECIFIC SAFETY RULES",

"GUIDELINES FOR EXTENSION

CORDS" and "SYMBOLS" before using

this pad sander.

Verify the following every time the pad

sander is used:

1. Sander cord is not damaged.

2. Safety glasses and dust mask are

being worn.

3. Hearing protection is being worn.

4. Sandpaper is the correct type for

the job.

5. Sandpaper is in good condition and

is properly installed.

Failure to observe these safety rules will

significantly increase the risk of injury.

WARNING

!

ASSEMBLY AND OPERATING

Fig. 6

!

Fig. 7

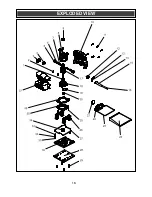

Summary of Contents for 241-9946

Page 16: ...EXPLODED VIEW 16...