14

SANDING – cont’d

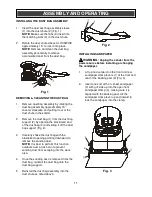

Upon completion of the sanding operation, turn

the sander OFF by pressing on the opposite

side of the ON/OFF switch. Wait until the

sanding pad comes to a complete stop before

removing it from the workpiece.

WARNING:

Your sander should only be

turned ON when the entire surface of the

sanding pad is in contact with the workpiece.

Failure to follow this sanding procedure

could result in loose sandpaper which could

result in possible injury.

NOTE: Hold the sander using the grip on top

of the sander. Be careful NOT to cover the

motor cooling vents with your hand. Motor

damage may occur from over heating if the

cooling vents are covered.

DO NOT FORCE THE SANDER. The weight of

the sander usually provides adequate pressure.

Let the sander and the sandpaper do the work.

Applying added pressure will slow the motor,

increase the wear on the sandpaper and greatly

reduce the sander speed. Motor damage may

occur if excessive downward pressure is

applied. It will also create an inferior finish on

sanded work. Any finish or resin on wood will

soften from the frictional heat, causing the

sandpaper to become clogged very quickly. Do

not sand in one spot too long as the sander’s

rapid action may remove too much material,

making the surface uneven.

Extended periods of sanding may tend to

overheat the motor. If this occurs, turn sander

OFF, wait until the sanding pad comes to a

complete stop and remove it from the

workpiece. Check to make sure your hand has

not been covering the cooling vents. Let the

motor cool before continuing the sanding

operation.

ASSEMBLY AND OPERATING

!

Summary of Contents for 241-9946

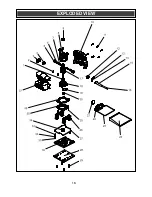

Page 16: ...EXPLODED VIEW 16...