Guidance MP-888 - Supplement to the manual of instructions

10/10

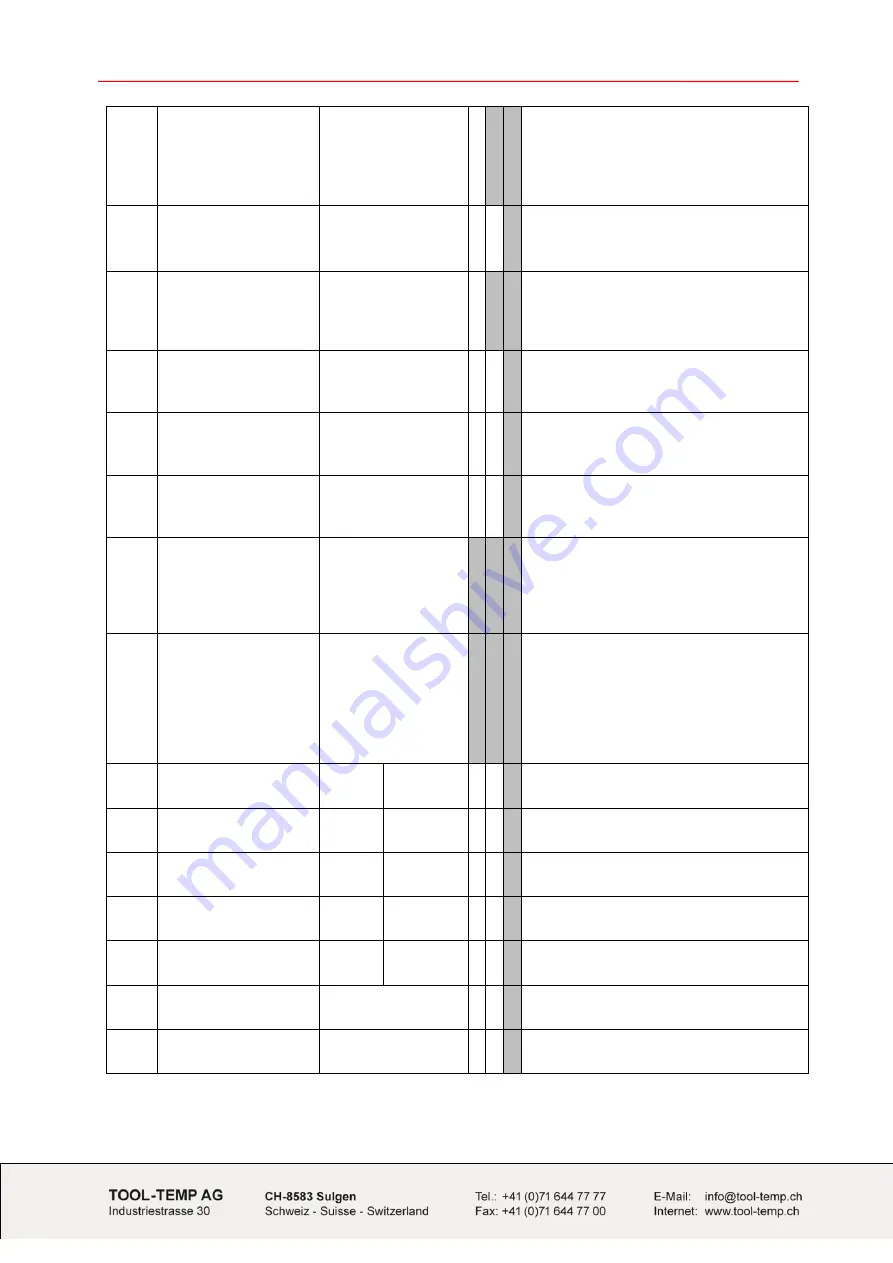

P43

Hysteresis cooling

Setting depends

on model

(0.2...25.0°C)

(0.4...45.0°F)

Period between ON and OFF of cooling.

This value has to be adjusted correctly

according to the controller adjustment

tables for temperature control units and

chillers.

P44

Differential portion

heating and cooling,

controller parameter

Setting depends

on model

(0...100%)

Differential portion of the PID control.

Controls the max. speed of the

controller

P45

Relation between

cooling- and heating

capacity

0

(1...50)

Adjusting of the cooling capacity

0:

2-point cooling (Standard)

1: cooling = heating capacity

50: cooling > heating capacity

P47

Minimal switching

time cooling,

controller parameter

1s

(0.5...9s)

Minimal switching time for cooling relay.

Only active if P45 is higher than 0

P48

Minimal switching

time heating,

controller parameter

2s

(1...9s)

Minimal switching time for heating relay.

If P45 = 0, so also relevant for the

cooling relay

P49

Cycle time,

controller parameter

15s

(6...255s)

Controller time base of PWM-outputs

Time of the analyse of the control

system to define the variable

P53

Flow unit

0: Flow OFF

1: Impulse (Hz)

2: litres/min

3: US gallons/min

4: Imperial gal./min

Flow unit to display

1 US gallon

= 3.785 litres

1 Imperial gallon = 4.546 litres

P60

Flow measurement

Calibration table

0 = Manual

1 = Small units 1

2 = Medium units

3 = Large units

4 = Reserved

5 = Small units 2

6 = Reserve

Selection of the calibration table for flow

measurement

P61

Flow measurement

point 1

x Hz

y l/min

Relevant calibration curve for flow

measurement depending on P60

P62

Flow measurement

point 2

x Hz

y l/min

Relevant calibration curve for flow

measurement depending on P60

P63

Flow measurement

point 3

x Hz

y l/min

Relevant calibration curve for flow

measurement depending on P60

P64

Flow measurement

point 4

x Hz

y l/min

Relevant calibration curve for flow

measurement depending on P60

P65

Flow measurement

point 5

x Hz

y l/min

Relevant calibration curve for flow

measurement depending on P60

P66

Lower alarm limit

(P61)

30%

Only valid for automatic node (P3=1) to

calculate the alarm point

P67

Upper alarm limit

(P65)

10%

Only valid for automatic mode (P3=1) to

calculate the alarm point