Guidance MP-888 - Supplement to the manual of instructions

7/10

3. Selection of the controller programme

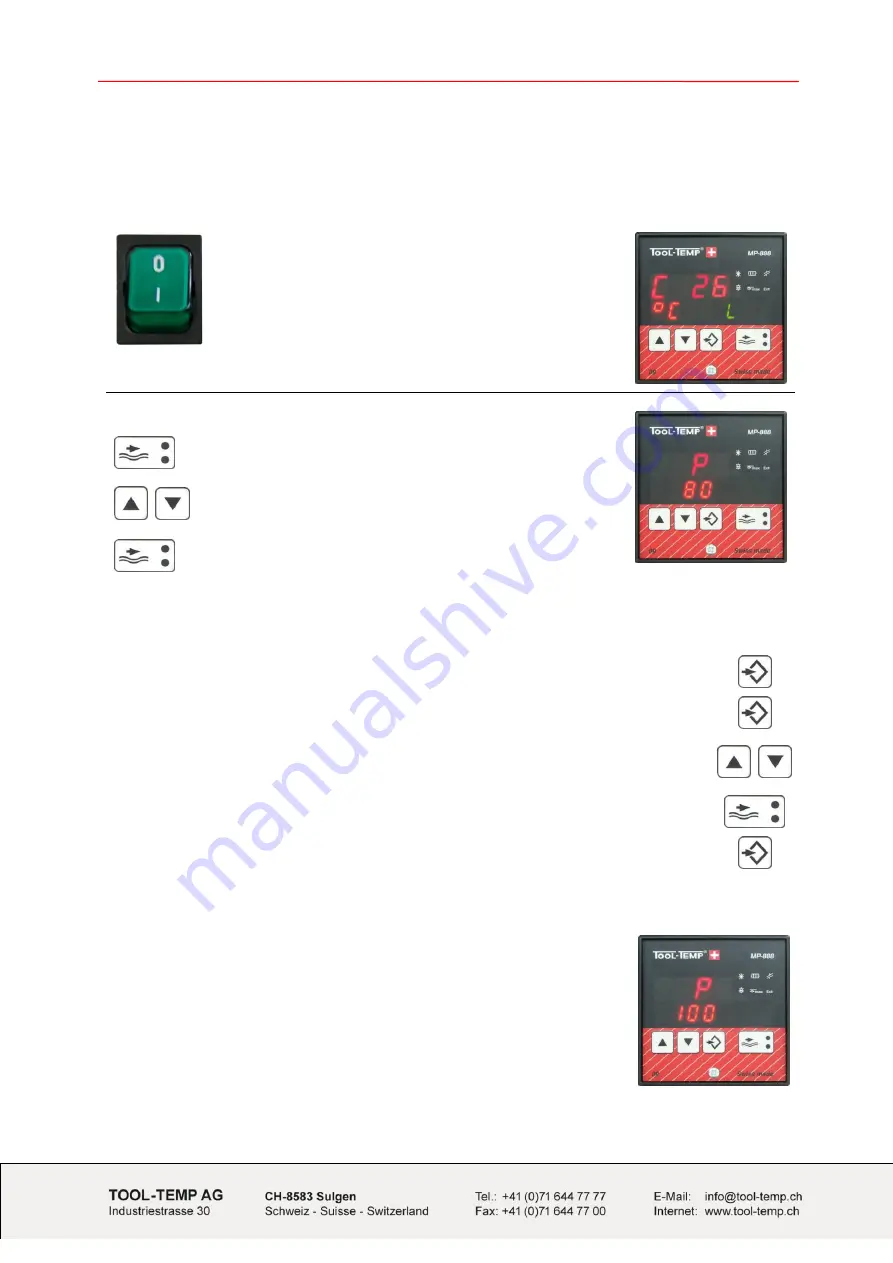

By starting the controller, the software-version is first shown (C-30) and afterwards the programme

number (P80).

Each temperature control unit or water chiller requires a different programming of the parameters.

The different parameters adjustments are saved in each program.

Start the unit, on the display follows…

up:

Software-version (C30)

down left:

Temperature unit in °C

down right:

Flow unit in liters per minute

P80

Software-version

Press button twice

With the arrow buttons choose the required programme

(see overview controller programmes)

Press button once to save

4. Navigation in the controller

Enter into the controller and navigate to the different parameter:

To enter into the programme of the controller, the program button has to be pressed

for 3 seconds.

To move from parameter to parameter, press the programme button.

Setting the parameter value:

With the two arrow buttons the value of the parameters can be adjusted.

Save the parameter settings:

To save the parameter settings and get back to the control function, the flow button

must be pressed.

To save the parameter settings and move to the next parameter, the programme

button must be pressed.

For all units with special programming P100:

If a parameter will be changed the controller shows P100. Controllers with a

special programing have a written the parameters on a label on the

controller and in the manual of the model.