Disclaimer

To take full advantage of the unit, you should be familiar with the vehicle engine working principle.

All information, illustrations, and specifications contained in this manual are based on the latest information available

at the time of publication. The manufacturer resume the right of modify this manual and the machine itself with no

prior notice.

Safety Precautions

Read all service procedures and precautions, installation instructions and equipment operating manuals thoroughly. Failure

to observe these precautions, or the improper use of equipment, could result in property damage, serious injury or death.

Never allow improperly trained personnel to perform these procedures or operate the equipment.

Read the operating instructions before attempting to operate the unit. Keep this manual with the unit at all times.

Care must be taken as burns can occur from touching hot parts of the equipment or in the engine.

Do not operate equipment with a damaged cord or if the equipment has been dropped or damaged until it has been

examined by qualified service personnel.

Do not hang cords over the edge of the table, bench or counter, or come in contact with hot manifolds or moving fan

blades.

If an extension cord is needed, a cord with a rated current equal to or greater than that of the equipment should be

used. Cords rated for lower current than that of the equipment may overheat.

Always unplug equipment from electrical outlet when the machine is not in use. Never pull the cord when unplugging

from the outlet.

Make sure the equipment cools down completely before putting it away. Loop cord loosely around the equipment

when storing.

To protect against risk of fire, do not operate the equipment in the vicinity of open container containing flammable

liquid (gasoline).

Make sure that the unit is in the well-ventilation area when operating the fuel engine.

Keep lighted cigarettes, sparks, flames or other ignition sources away from fuel systems at all times.

Keep hair, clothes, fingers or the other body parts away from the running parts of the unit.

In order to avoid electric shock, keep away from the damp part of a working unit and avoid exposing it to the rain.

Please operate the unit according to the operation procedures in the manual. Only use the accessories

recommended by the manufacturer.

Do not switch on the ultrasonic system when there is no ultrasonic detergent in the ultrasonic cleaning chamber.

Otherwise, damage to the ultrasonic cleaner can be resulted.

Keep the unit well grounded.

Provide ventilation through an exhaust gas removal system, ventilation fans or large doors. Carbon monoxide gas,

which is odorless and colorless, can cause serious illness, injury or death.

Avoid contacting hot surfaces such as exhaust pipes, radiator, etc.

Before testing vehicles, put the transmission lever in NEUTRAL position, apply the parking brake, and block the front

wheels.

ALWAYS WEAR SAFETY GOGGLES. Common used glasses are NOT safety glasses.

When disconnecting any connector of the pressurized fuel hose, wrap the connector with towel to prevent the fuel

from spurting out. Spurted fuel may cause personal injury or fire.

Test liquid is used by the main unit. Detergent is used for on-vehicle cleaning. The ultrasonic cleaning uses specified

ultrasonic detergent.

Note: Specifying operations that require attention when operating the equipment.

Warning: Specifying a possible hazard that could result in damage to the machine or personal injury.

Summary of Contents for GDI

Page 1: ...Automotive Fuel Injector Tester PFI GDI GS6...

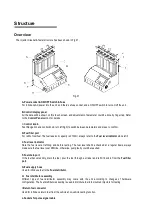

Page 16: ......