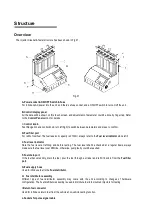

Installation

1) Move the machine onto the workbench after unpacking and loosen the strips on the outlet hoses.

2) Mount the pulse signal cables onto the sockets on the top right side of the machine.

3) Take the two adjusting bolts out from the kit and install them to the press plate on the top of the glass tube.

4) Take the two knurled nuts from the kit and install them on the adjusting bolts.

5) Take the fuel distributor from the kit and install it on the knurled nuts and tighten them with the pressing bolts.

6) Take the power cables out from the kit and insert it into the input socket at the bottom of the unit.

7)

Take the power cables out from the kit and insert it into the input socket of the ultrasonic cleaner.

Operating Procedures

Preparation

1) Remove the injector from the vehicle engine to check the o-rings for damage. Replace the damaged O-ring with another

same type O-ring to avoid leakage during testing. Put the outside of injectors in gasoline or detergent, and wipe them with

soft cloth after cleaning the outside oil sludge carefully.

2) Check the liquid level and refill test liquid when necessary. Fill the test liquid through the filler on the side of the unit and

observe the liquid level in the fuel level viewer.

Do NOT exceeding the Max line.

3) Turn on the power switch on the left side of the

Cabinet.

4) Fill ultrasonic detergent into the ultrasonic cleaning launder so that the needle valve of the injector is covered by the

detergent.

5) Connect the injectors with the correct couplers.

Note:

Test liquid and detergent won’t be provided by the manufacturer.

Cleaning & testing sequences

A complete cleaning and testing sequence shown below should be followed:

Ultrasonic cleaning;

Uniformity/Sprayability test;

Leakage test;

Injecting flow test;

Automatic test.

Select the corresponding parameter and set up according for various tests. For detailed operations, please refer to

Operation

and

Control Panel

section.

Tidy up after operating

Tidy-up should be done after cleaning and testing is completed:

Press [Drain] button to drain the test liquid into fuel tank.

Switch off the power.

Drain the injector detergent to its original bottle and then wipe the ultrasonic cleaner with soft cloth.

Clean the Injector Cleaner & Tester control panel with soft cloth.

Drain the test liquid from the tank into a container to avoid volatilization. Store the test liquid in a safe place if it can be

used again, or dispose of it in accordance with relevant regulations if it is too dirty.

Operation

Ultrasonic Cleaning

Injector Cleaner takes advantage of the penetrability and cavitation impact wave caused by ultrasonic wave traveling

Summary of Contents for GDI

Page 1: ...Automotive Fuel Injector Tester PFI GDI GS6...

Page 16: ......