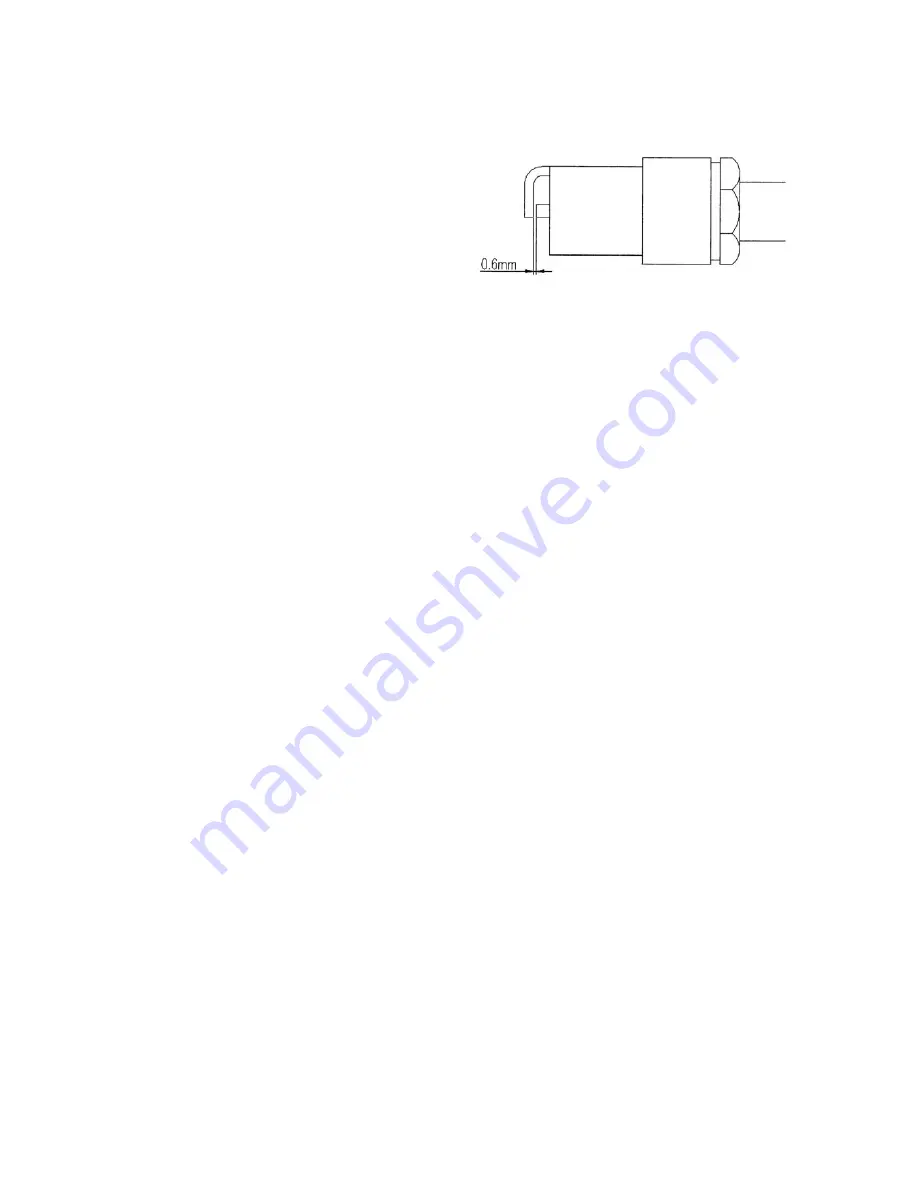

Spark gap: 0.5-0.6mm

■

GREASE GEARCASE

Use a grease pump, feed grease until it comes out of the base of blades.

■

ADJUSTING CARBURETOR

The carburetor has been adjusted at the factory . Should your unit need

readjustment due to the dif ference of altitude or ope rating conditions,

please let your skillful dealer make the adjustment.

■

THROTTLE WIRE

Throttle wire play should be 1-2mm.

AFTER 50 HOURS OF USE

Please check and tighten all the scr ews, bolts and nuts after the unit is

used at every 50 hours.

AFTER 100 HOURS OF USE

■

MUFFLER

a.

Remove the muffler, insert a screwdriver into the vent, and wipe away

any carbon buil dup. Wipe away any carbon buil dup on t he m uffler

exhaust vent at the same time.

-9-