Page 4

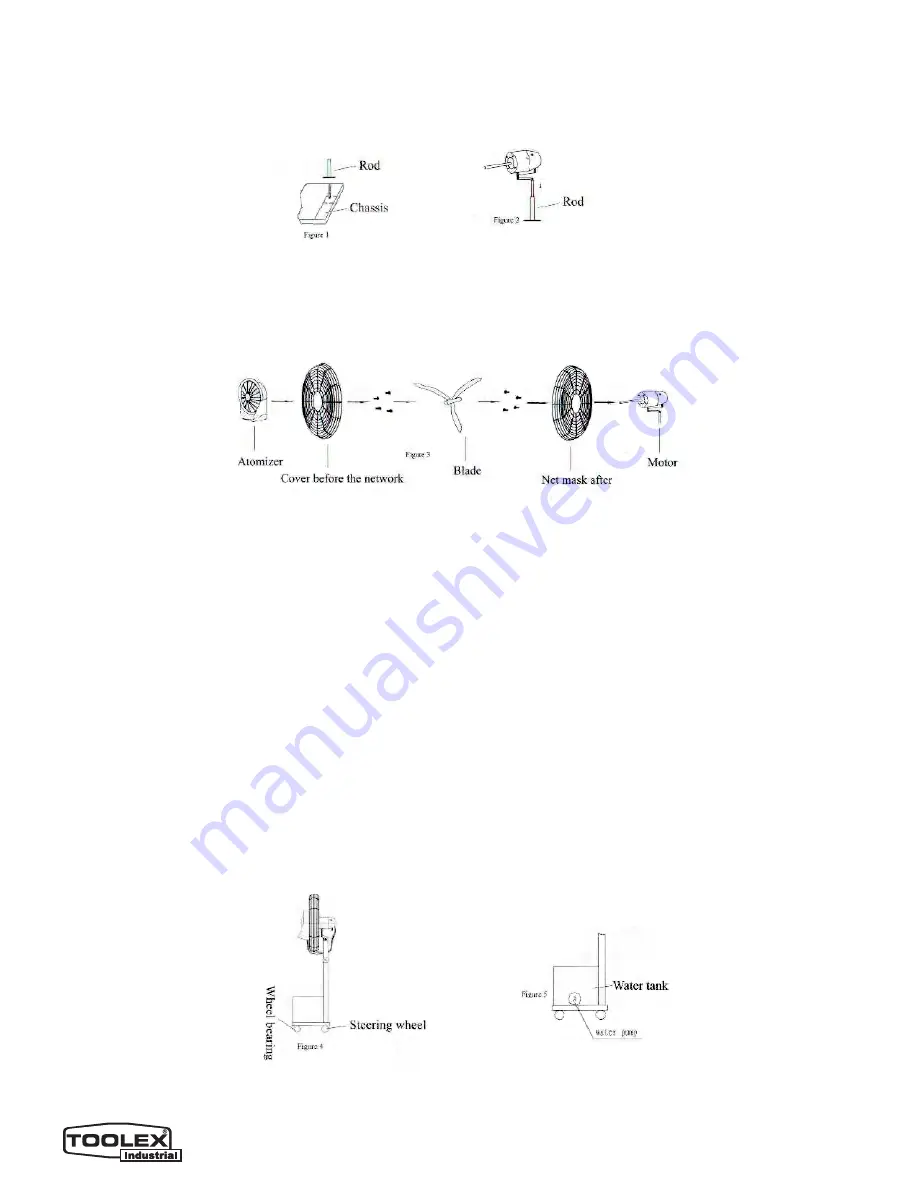

3. ASSEMBLY

1. Use M6*12 Bolt and M10 nut to fix bearing and rotation wheel on the under frame

2. Fix supporting shaft.

3. Put the water box on the under frame whilst fixing other components, to ensure the fan will

not fall. Add water to the 1/2 cbm water tank, put water pump in the water tank. The plug and

6mm water pipe for the pump should go through the small hole in the water tank lid. Then

cover the water tank lid.

4. Plug in the motor connecting point to the supporting shaft, screw the bolt and adjust the

motor position.

5. Fix the back net to the fan.

6. Install the fan to the motor axle.

7. Fix the atomoization to the front net by bolt, and then connect the front and back net.

8. Use stick to rotate the fan to check it can rotate normally. See fig. 4 and fig. 5.

9. Insert Core plug, dia 6mm, dia. 8mm water pipe of the automization respectively to the 4 core

socket, 6mm, 8mm water in and out whole socket on the top of supporting shaft.

10. Plug 3 core motor plug in the 3 core socket.

11. Plug 2 core motor plug in the 2 core socket, plug 6mm water pipe to 6mm hole socket, 8mm

water pipe to 8mm hole socket, the other side to the small hole in the water tank lid.

12. Insert fan power cable to the related power socket.