Page 7

TROUBLE SHOOTING GUIDE

TROUBLESHOOTING GUIDE

The air compressor should be turned off and unplugged from the power source before any

maintenance is performed as well as the air bled from the tank and the unit allowed time to

cool. Personal injuries could occur from moving parts, electrical sources, compressed air, or hot

surfaces.

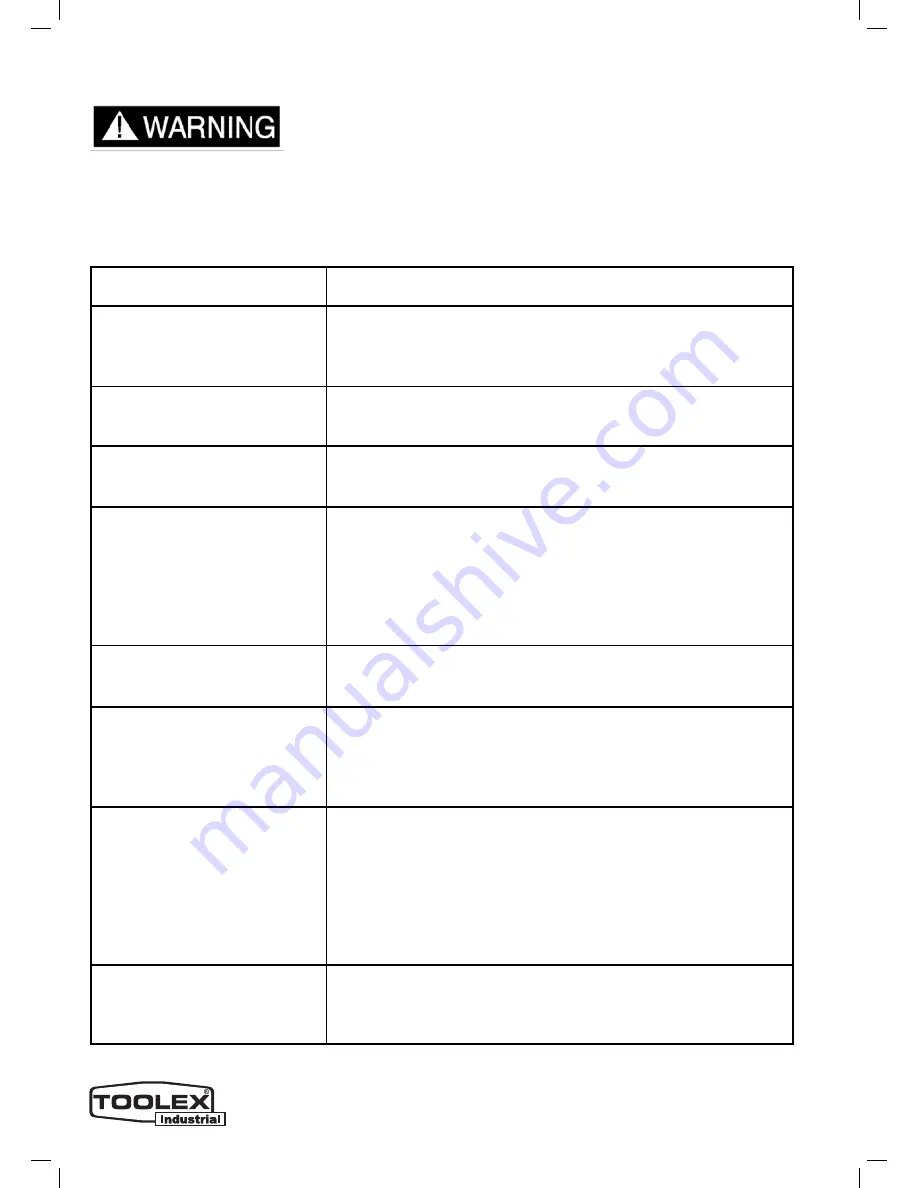

Problem

Possible Correction

Air leaks at the check valve or

at the pressure relief valve.

A defective check valve results in a constant air leak at the

pressure release valve when there is pressure in the tank and

the compressor is shut off. Drain the tank, then remove and

clean or replace the check valve.

Air leaks between head and

cylinder.

Be sure of proper torque on head bolts. If leak remains, contact

a service technician.

Air leak from safety valve

Operate the safety valve manually by pulling on the ring. If the

valve continues to leak when in the closed position, it should be

replaced.

Pressure reading on the

regulated pressure gauge

drops when an accessory is

used.

If there is an excessive amount of pressure drop when the

accessory is used, replace the regulator.

NOTE:

Adjust the regulated pressure under flow conditions (while

accessory is being used). It is normal for the gauge to show

minimal pressure loss during initial use of the tool.

Excessive tank pressure.

Move the Auto-On/Off lever to the Off position. If the unit

doesn’t shut off, unplug it from the power source and contact a

service technician.

Motor will not start.

Make sure power cord is plugged in and the switch is on.

Inspect for the proper size fuse in your circuit box. If the fuse

was tripped reset it and restart the unit. If repeated tripping

occurs, replace the check valve or contact your service

technician.

Excessive moisture in the

discharge air.

Remove the water in the tank by draining after each use. High

humidity environments will cause excessive condensation.

Utilize water filters on your air line.

NOTE:

Water condensation is not caused by compressor malfunction.

Be sure the compressor’s air output is greater than your tool’s

air consumption rate.

Air leaks from the tank body or

tank welds.

Never drill into weld or otherwise modify the air tank or it will

weaken. The tank can rupture or explode. Compressor cannot

be repaired. Discontinue use of the air compressor.

7.