Page 2

2

TABLE OF CONTENTS

SPECIFICATIONS

Safety Instructions..............................................................................................................................3 - 5

Contents of Package .......................................................................................................................................6

Getting to Know Your Sander ..........................................................................................................................7

Assembly ........................................................................................................................... 7 - 9

Adjustments .......................................................................................................................... 9 - 11

General Use........................................................................................................................................12

Troubleshooting........................................................................................................................................13 - 14

Maintenance ...................................................................................................................................14

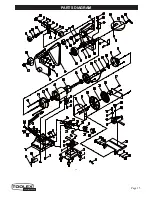

Parts Diagram ................................................................................................................................15

This owner’s manual is not a teaching aid and is intended to show

assembly, adjustments, and general use.

Motor ..................................................550W S2 30min, 230V, 50Hz

Motor Speed (variable) ...................................... 2,000 - 2,850 RPM

Belt Size ....................................................................... 25 x 762mm

Belt Speed (variable) ....................................... 1,900 - 2,700 SFPM

Belt Table Size ..................................................... 146mm Diameter

Belt Table Tilt ........................................................................... 0-45°

Disc Size .............................................................................. 150mm

Disc Speed (variable) ........................................ 2,000 - 2,850 RPM

Disc Table .................................................................... 204x135mm

Disc Table Tilt .......................................................................... 0-45°

Miter Gauge ....................................................................... Included

Miter Gauge Slot ........................................................... 16x6.5 mm

Base Size .................................................................... 170x235mm

Dust Ports (2) ............. 45mm OD/ 38mm ID & 38mm OD/ 32mm ID

Net Weight ......................................................................... 13.7 kgs

Shipping Weight .................................................................... 15 kgs

Summary of Contents for 598557

Page 15: ...Page 15 PARTS DIAGRAM 15 ...