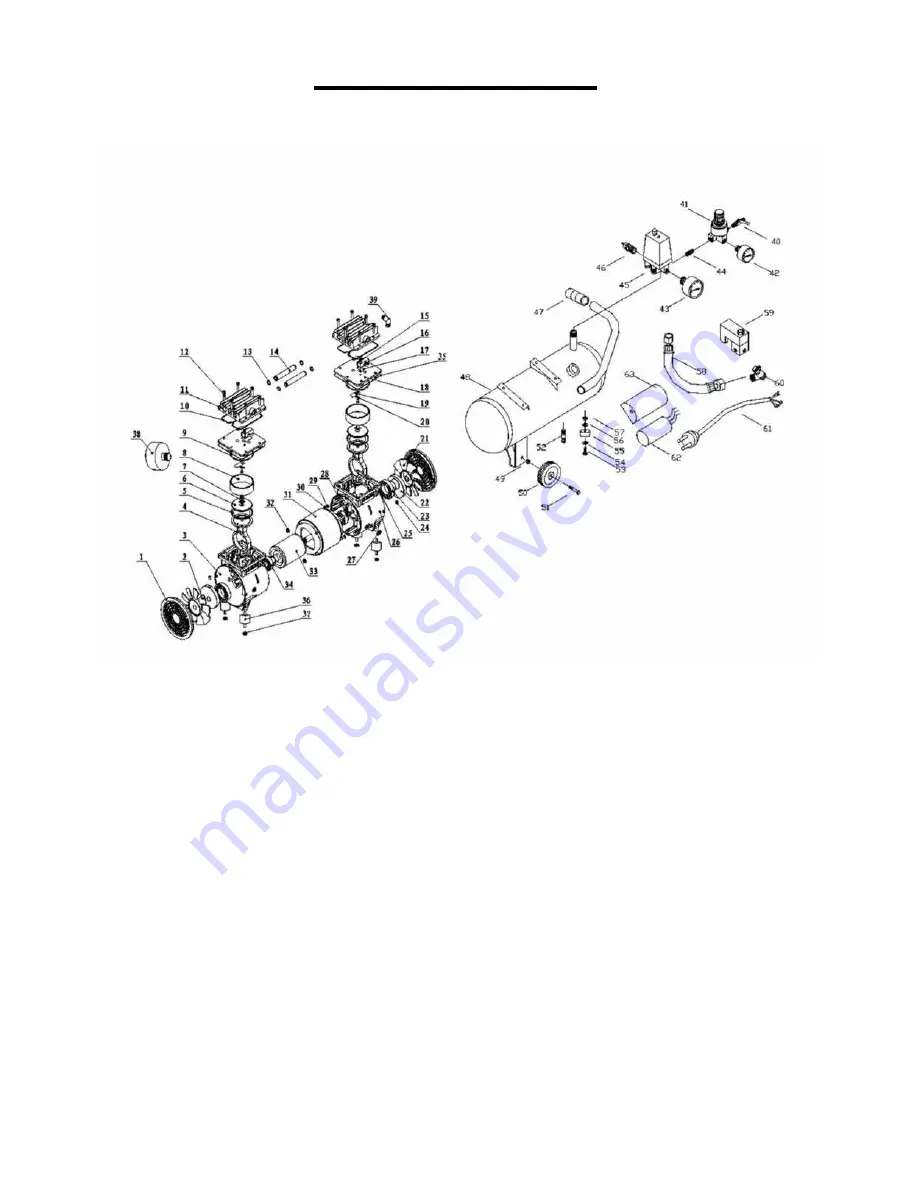

PARTS DIAGRAM

1. Cover

2. Left Fan

3. Left Crankcase

4. Connecting Rod

5. Piston Cup

6. Binder Plate

7. Con Rod Bolt

8. Cylinder

9. Cylinder Seal

10. Head Seal

11. Cylinder Head

12. Head Bolt

13. ‘O’ Ring

14. Transfer Pipe

15. Valve Plate Bolt

16. Valve Block

17. Reed Valve

18. Reed Valve

19. Valve Plate

20. Washer

21. Right Fan

22. Shaft Seal

23. Bearing 6908-2z

24. Bearing Bolt

25. Bearing Bolt

26. Right Crankcase

27. Protection Ring

28. Assembly Bolt

29. Assembly Bolt

30. Spring Washer

31. Stator

32. Assembly Nut

33. Rotor

34. Bearing 6203-2z

35. Adjusting Washer

36. Rubber Mount

37. Spring Washer

38. Air Filter

39. Elbow

40. Deflating Tap

41. Regulator

42. Outlet Pressure gauge

43. Tank Pressure gauge

44. Connector

45. Pressure Switch

46. Safety Valve

47. Handle

48. Tank

49. Wheel Nut

50. Wheel

51. Bolt (Axle)

52. Tank Drain Cock

53. Bolt

54. Washer

55. Cushion Foot

56. Washer

57. Nut

58. Pipe

59. Actuated Valve

60. Non Return Valve

61. Plug and Lead

62. Capacitor

63. Capacitor cover

4.