Protection Device And Troubleshooting

1. Protection Device for control substrate

Fuse (250V/3A)

When over-high voltage is input or the part on the substrate

breaks down, this fuse will be melted to prevent elements at

rear like the compressor from being damaged.

2. Protection Device for Fan Motor

Fuse (250V/3A)

When the cooling fan motor breaks down to cause excessive

current, this fuse will be melted to avoid electric hazards.

3. Protection Device for Freezing System

Temperature Sensor

When the freezing system is lack of maintenance or the refrigerant

leaks, backflow temperature will become too high and cause the

compressor to overheat. Thus, the compressor can be stopped

opportunely by the temperature sensor.

4. Protection Device for Compressor

Current Sensor

The current sensor can detect operation status of the compressor

when the dryer is running. In case of over-current, the compressor

will be stopped at once.

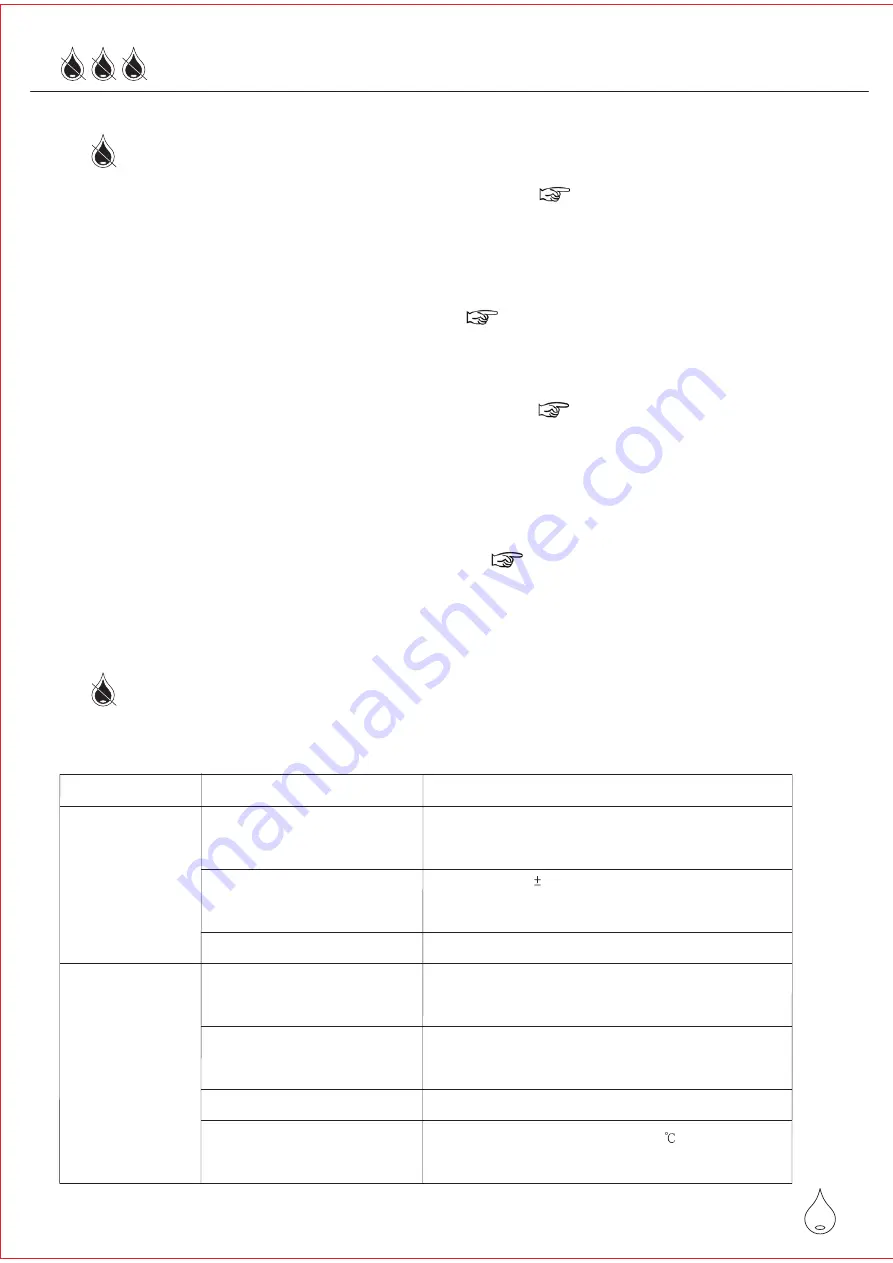

Protection Device

Troubleshooting

1. Can't start

Failure

Possible Reason

Resolution

Power switch trips or breaks down. Check power switch and make sure if voltage is normal.

Abnormal power supply

causes the fuse of the control

substrate to melt.

Supply power of 5% of rated voltage in accordance

with the nameplate and replace the fuse.

Control substrate breaks down.

Replace a new one.

Overload trip

indicator on

Condenser is blocked.

Remove dust or impurities out of the surface of the fin in

compliance with service instructions.

Cooling fan breaks down to

cause the fuse of the fan to melt.

Replace a fan motor and a fuse.

Refrigerant leaks.

Vacuum after repair and re-fill refrigerant.

Rated environment temperature

exceeds.

When ambient temperature is over 40

, relocate the

equipment or add ventilation facilities.

No display

-10-

Summary of Contents for AD-005

Page 1: ...Operating Manual Freezing Compressed Air Dryer Http www dryer com tw E mail dryer dryer com tw...

Page 17: ...Footnote 16...

Page 18: ...Footnote 17...

Page 19: ...Footnote 18...

Page 20: ......