Customer Helpline

1300 889 028

13

Operating Instructions

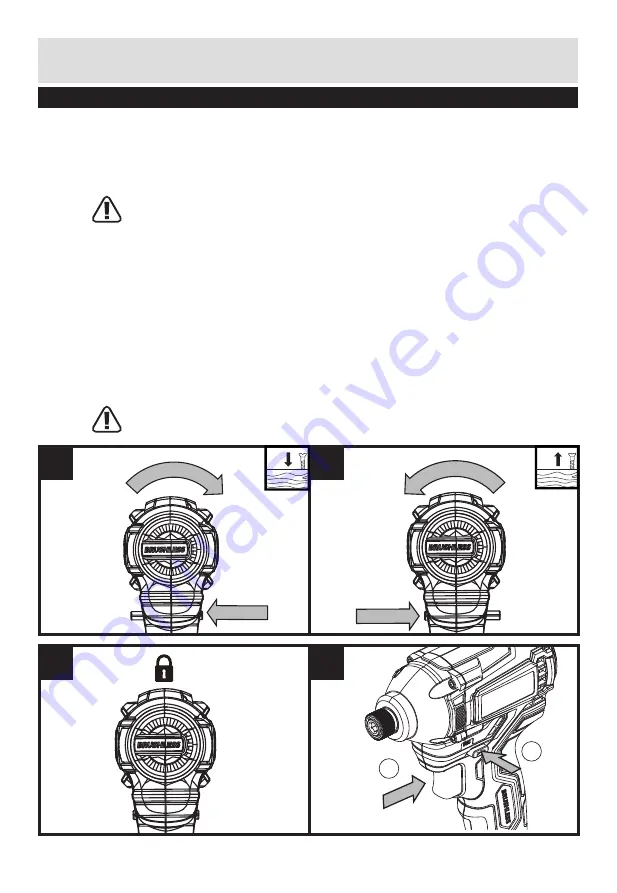

4. REVERSIBLE (SEE FIG E1, E2)

Forward rotating: push the forward/reverse rotation control to the left (the drill points

away from you). It is used for drilling and screw driving.

Reverse rotation: push the forward/reverse rotation control to the right (the drill points

away from you). It is used for remove screws or release a jammed drill bit.

WARNING: Never change the direction of rotation when the chuck is rotating,

wait until it has stopped!

5. SWITCH LOCK (SEE FIG F)

The switch trigger can be locked in the OFF position. This helps to reduce the possibility

of accidental starting when not in use. To lock the switch trigger, place the rotation

control in the center position.

6. ON/OFF SWITCH (SEE FIG G)

Depress to start and release to stop your driver.

The On/Off Switch is fitted with a brake function which stops your chuck immediately

when you quickly release the switch.

It is also a variable speed switch that delivers higher speed and torque with increased

trigger pressure. Speed is controlled by the amount of On/Off switch depression.

WARNING:

Do not operate for long periods at low speed because excess heat will

be produced internally.

E1

F

E2

G

1

2