9

Operation

WARNING

- if any parts are missing, do not operate this tool until the missing parts are replaced.

Failure to do so could result in possible serious personal injury.

Lubrication

This tool requires lubrication before using the tool for the first time and before each

use. If an inline oiler is used, manual lubrication through the air inlet is not required.

Note:

The work surface can become damaged by excessive lubrication. Proper

lubrication is the owner’s responsibility. Failure to lubrication the tool properly will

dramatically shorten the life of the tool and void your warranty.

1.

Disconnect the air supply from the tool to add lubricant.

2.

Turn the tool so the air inlet is facing up. Place 4-5 drops of 30W non-detergent oil (included) into air

inlet.

3.

After adding oil, run toll briefly. Wipe off any excess oil from the exhaust.

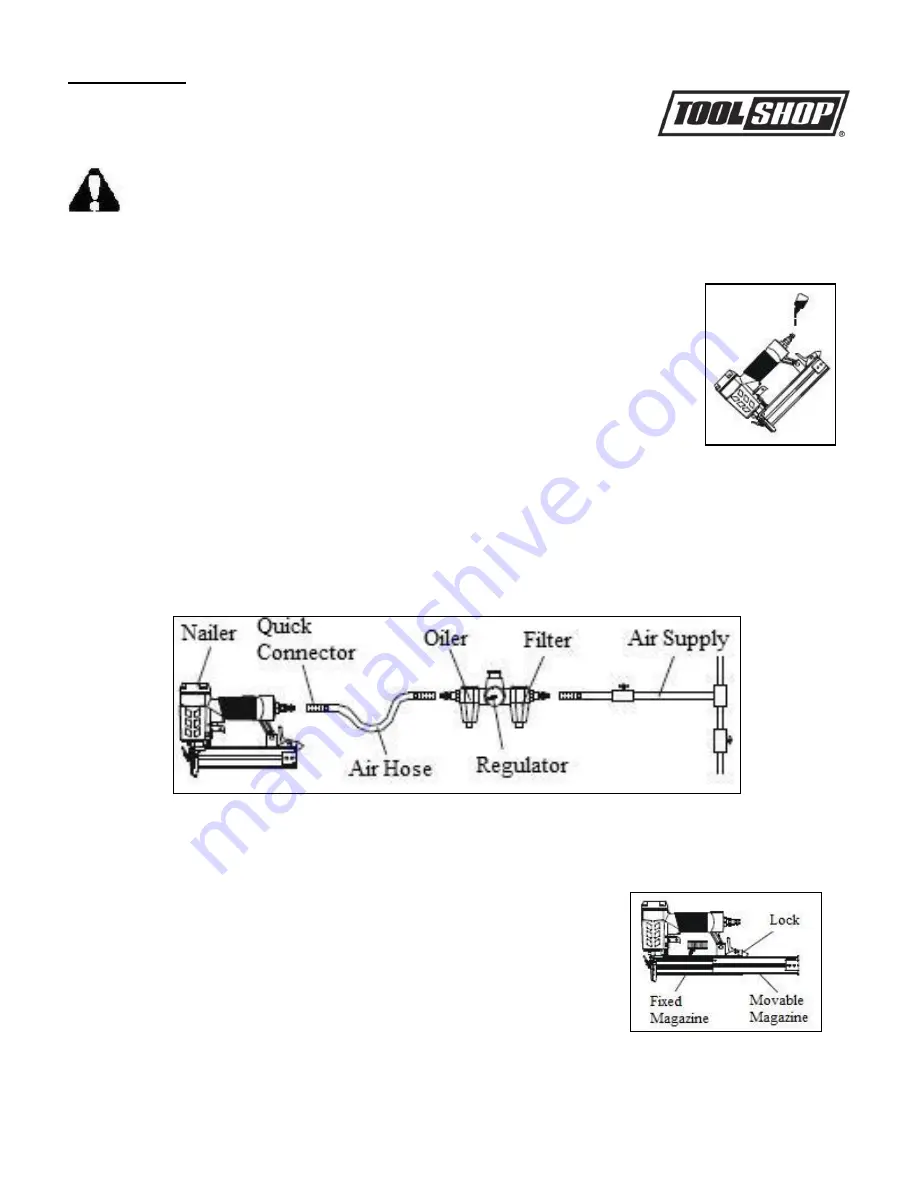

Recommended Hookup

Your air tool is fully assembly when you receive it. Before using it, attach the air line and desired air

system accessories. See below for the recommended accessories and connection order. Be sure the air hose

is depressurized when installing or removing adapters to the air line.

Loading the fasteners

Caution:

Always disconnect the tool from the air supply before loading the

fasteners.

1. Depress the lock to release the movable magazine and pull the magazine

out fully.

2. Place a full clip of the specified type and size fasteners on the fixed

magazine, up to 100 fasteners may be loaded in the magazine.

3. Push the movable magazine forward until it was locked.