16

WARNING:

When servicing, use only original equipment replacement parts. The use of any

other parts may create a safety hazard or cause damage to the sander.

Any attempt to repair or replace electrical parts on this sander may create a safety hazard unless

repairs are performed by a qualified technician. For more information, call the Toll-free Helpline, at 1-

866-349-8665.

Always order by PART NUMBER, not by key number.

Key #

Part #

Part Name

Quantity

1

3011060024 Housing assembly

1

2

3150060005 Brush holder support

2

3

2030070001 Brush holder

2

4

1230010120 Carbon brush

2

5

3140080036 Switch cover

1

6

1061250001 Switch

1

7

1020060021 Stator

1

8

3140060001 Rubber buffer

2

9

4030010106 Tapping screw ST3.9*19

5

10

1250010002 Tapping screw

1

11

4030010099 Tapping screw ST3.9*14

2

12

3150020001 Cord clamp

1

13

3140010054 Cord guard

1

14

1190030006 Cord

1

15

4010010053 Bearing 607 2RS

1

16

3140020023 "O" ring

1

17

1010060020 Rotor

1

18

4010010054 Bearing 6000 2RS

1

19

3180040048 Vacuum adaptor

1

20

3150010087 Fan

1

21

2030030196 Counterbalance

1

22

6150030048 Dust Bag

1

23

2010130030 Eccentric seat

1

24

2030170007 Dustproof washer

1

25

2020130001 Bearing block

1

26

4010010084 Bearing 6000RS

1

27

2030020033 Washer

1

28

4020080004 Hexagon screw M5*16

1

29

2030160007 Large washer

1

30

1150020007 Bubber backing pad

1

31

4040030011 Spring washer 5

5

32

4020010081 Special screw M5*14

4

PARTS LIST

!

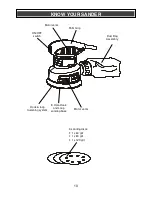

Summary of Contents for 241-9942

Page 15: ...15 EXPLODED VIEW...