A

(mm)

E

(mm)

E

(mm)

E

(mm)

100

630

595

630

630

630

780

745

780

780

780

110

620

585

620

620

620

770

735

770

770

770

120

610

575

610

610

610

760

725

760

760

760

130

600

565

600

600

600

750

715

750

750

750

140

590

555

590

590

590

740

705

740

740

740

150

580

545

580

580

580

730

695

730

730

730

160

570

535

570

570

570

720

685

720

720

720

170

560

525

560

560

560

710

675

710

710

710

180

550

515

550

550

550

700

665

700

700

700

890

190

540

505

540

540

540

690

655

690

690

690

880

200

530

495

530

530

530

680

645

680

680

680

870

210

520

485

530

530

530

670

635

670

670

670

860

220

660

625

660

660

660

850

230

650

615

650

650

650

840

240

640

605

640

640

640

830

250

630

595

630

630

630

820

260

620

585

620

620

620

810

270

610

575

610

610

610

800

280

600

565

600

600

600

790

2

– English

EN

3.5 - Installation of fixing brackets and gear motor

3.5.

1

– Installation of rear fixing bracket

Calculate the position of the rear bracket using

graph 2.

This graph serves to establish

dimensions A

and

B

and the

value of the max-

imum opening angle

of the leaf.

Important

– The values of A and B must

be similar to allow linear movement of the automation.

01.

Measure

dimension C

(

fig. 4

) on the fixing side;

02.

On

graph 2

, identify

dimension C

found and trace a horizontal line that

determines the value of

dimension B (*)

as shown in the example of

fig. 5

;

the meeting point with line “

r.i.l

” (installation line recommended) deter-

mines the value of the angle of maximum opening. From this point, trace a

vertical line as shown in the example of

fig. 5

to determine the value of

dimension A

.

If the angle found does not correspond to the requirements, adapt dimen-

sion A and if necessary dimension B, so they are similar.

(*) Do not use values of dimension B below the line “

t

” (see graph 2).

03.

Before being fixed to the wall the bracket must be sealed to the specific fix-

ing plate (

fig. 7

); if necessary the bracket can be cut adapting values of

dimensions A and B.

Note

– The bracket supplied for the Toona series 4-5 gear motor, meas-

ures 150 mm in length; in the event of special applications or in the event

of a gate equipped with external opening (

fig. 6

) use bracket mod. PLA6

(accessory).

CAUTION!

– Before securing the rear bracket, check the fixing zone

of the front bracket is in a solid part of the leaf, as this bracket must

be fixed at a different height of the rear bracket (fig. 8).

04.

At this point, fix the bracket using dowels, screws and washers required

(not supplied).

3.5.

2

– Installation of front fixing bracket

The front bracket must be fixed to the gate leaf respecting the values of

dimen-

sions D

and

E

(

Fig. 4

).

Note

– The bracket supplied for the Toona series 4-5 gear motor must be weld-

ed directly to the gate leaf. If this is not possible, use bracket mod. PLA8

(accessory).

01.

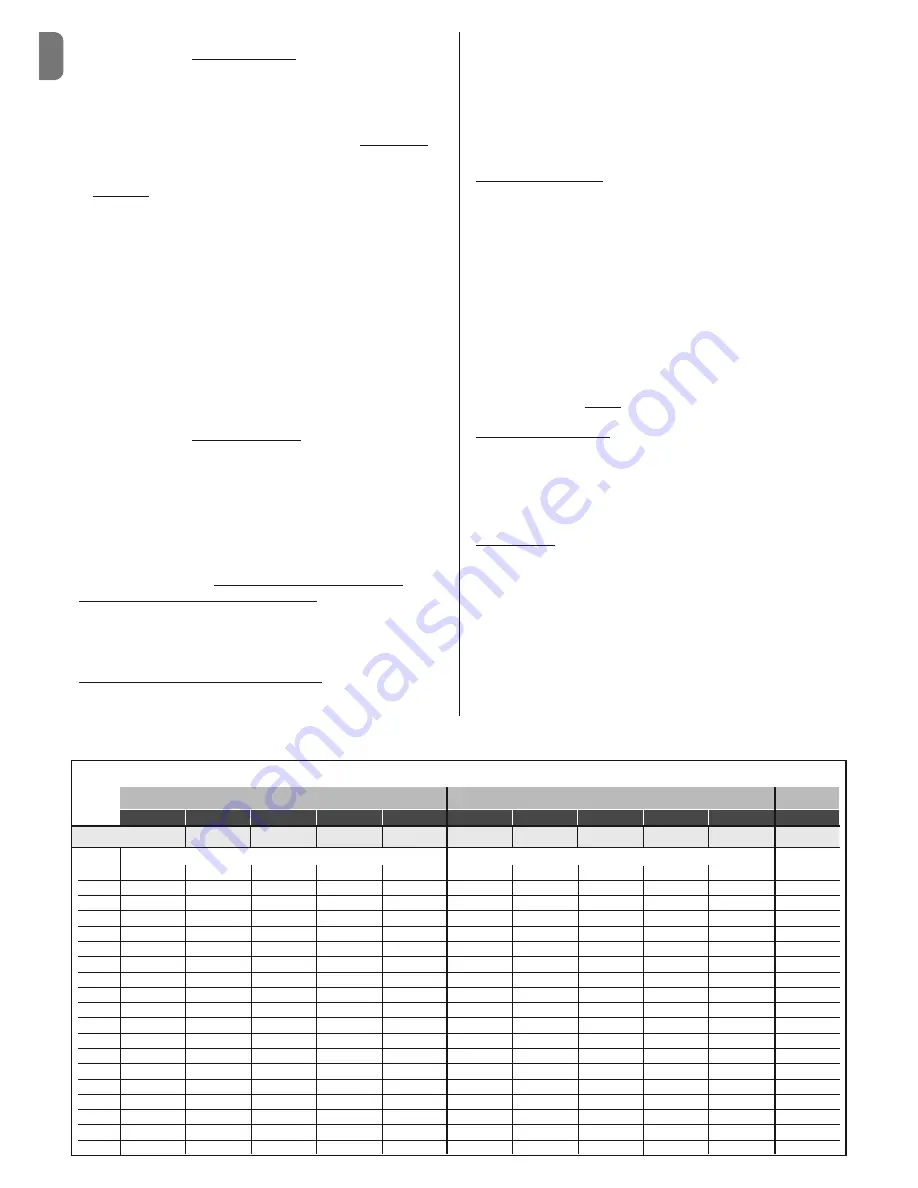

Establish the value of

dimension E

using

Table 1

;

02.

Establish the height in which to position the front bracket, referring to

fig. 8

;

03.

Fix the bracket to the solid part of the gate leaf.

3.5.

3

– Installation of the gear motor on the fixing brackets

•

Installing the gear motor on

the rear bracket

:

01.

Fix the gear motor to the bracket as shown in

fig. 9

using the screw,

washer and nut supplied;

02.

Tighten the nut to the end and then loosen by 1/10 of a turn to allow min-

imum clearance between the parts.

•

Installing the gear motor

on the front bracket

:

01.

Fix the gear motor to the bracket as shown in

fig. 10

using the screw,

washer and nut supplied;

02.

Tighten the screw to the end.

03.

Fix the label provided in the package, dealing with the unblocking and

blocking operations of the gear motor, permanently close to the gear motor

3.6 - Setting the mechanical limit switch

The mechanical limit switch allows to set the stop position of the gate leaf, in

this way, it is not necessary to use the stop blocks and the leaf does not hit

against these at the end of the manoeuvre.

•

Toona

series 4-5 (24 V)

WARNING

– In the event of applications with a gate equipped with open-

ing towards the outside (fig. 6) it is necessary to invert the power supply

wires.

Set the

limit switch in Opening

of the gear motor as follows:

01.

Unblock the gear motor as shown

in fig. 16

;

02.

Loosen the mechanical stop screw;

03.

Bring the gate leaf manually to the

Open

position required;

04.

Then, bring the mechanical stop to the end of the pin and block the screw

(

fig. 11

).

05.

Bring the leaf manually to the

Close

position and block the gear motor.

Note

–

Gear motors mod. TO4006 and mod. TO5016, are provided with a

mechanical limit switch also for the Closing manoeuvre.

If in possession of

one of these models, to set the mechanical limit switch repeat the procedure

described above, with a variation at

point 03

, in this case, bring the gate leaf

manually in the required Closing position.

•

Toona

series 4-5 (230 V)

The Toona series 4-5 gear motors arranged for an alternate current of 230V,

come with mechanical stop with micro switch which, on contact with the pin

interrupts the electrical power supply.

WARNING

– In the event of applica-

tions with a gate equipped with opening towards the outside (fig. 6) it is

necessary to invert the power supply wires.

• Toona

series 7

Set the

limit switch in Opening

and

Closing

of the gear motor;

01.

Unblock the gear motor as shown in

fig. 16

;

02.

Move the leaf manually until the mechanical stop screw is visible and

loosen the screw;

03.

Bring the gate leaf manually to the

Open

position required;

04.

Then, bring the mechanical stop to the end of the pin and block the screw

(

fig. 12

);

05.

At this point repeat this procedure bringing the leaf manually to the position

of maximum

Closure

, to set the limit switch in Closure;

06.

Finally, block the gear motor.

Toona 4

Toona 5

Toona 7

TO4005

TO4006

TO4015

TO4605

TO4024

TO5015

TO5016

TO5605

TO5024

TO5024I

TO7024

D

(mm):

730

695

730

730

730

880

845

880

880

880

1070

TABLE 1

Summary of Contents for TO4005

Page 2: ......

Page 9: ...EN IT FR ES DE PL NL IX EN Images ...

Page 16: ...XVI 7 6 D E A B C ...

Page 17: ...XVII 2 1 9 8 Toona 4 5 F 44 mm Toona 7 F 50 mm F ...

Page 18: ...XVIII 1 2 3 10 2 3 1 Toona 4 5 Toona 7 ...

Page 19: ...XIX 12 11 100 mm max Toona 4 5 Toona 7 ...

Page 20: ...XX 2 1 14 1 2 13 ...

Page 21: ...XXI 1 3 2 16 ENC M M AP COM CH 15 Toona 4 5 24 V Toona 7 24 V 24 V 230 V Toona 4 5 230 V ...

Page 22: ......

Page 23: ......