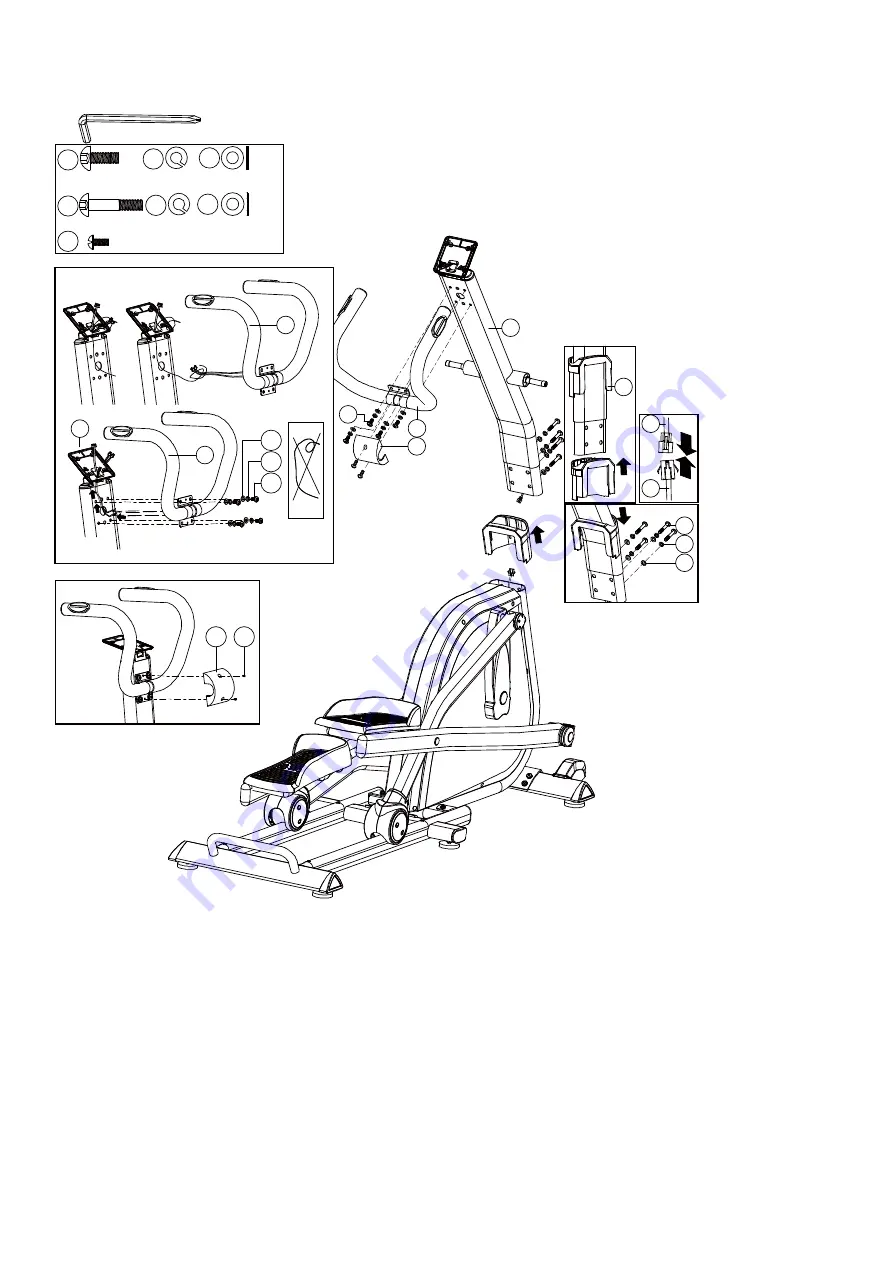

STEP 3

Step-3

68

M5*12

D15.4

M8*20

D16

9

8

x4

7

41

D15.4 D16

8

x4

7

M8*50

x2

3-1

a

b

d

c

3-5

3-2

3-3

3-4

10

49

9

7

8

81

81

67 68

81

67

41

8

7

87

29

30

9

1) Suggest assembling this step by two persons.

2) First, lift up the upper protective cover (49) as fig. 3-1. Then connect computer

cable (29 & 30) as fig.3-2.

3) Insert the handlebar post (10) on the main frame and tighten it by using the flat

washer (8), the spring washer (7) and the Allen bolt (41). Place down the upper

protective cover (49) and make it tight on the main frame as fig.3-3.

4) Assemble the handlebar welding set (81) to the handlebar post (10) by using the

flat washer (8), the spring washer (7), and the Allen bolt (9) as fig.3-4.

5) Assemble the protective cover (67) by using the bolt (68) as fig.3-5.

14