P

P

A

A

R

R

T

T

S

S

L

L

I

I

S

S

T

T

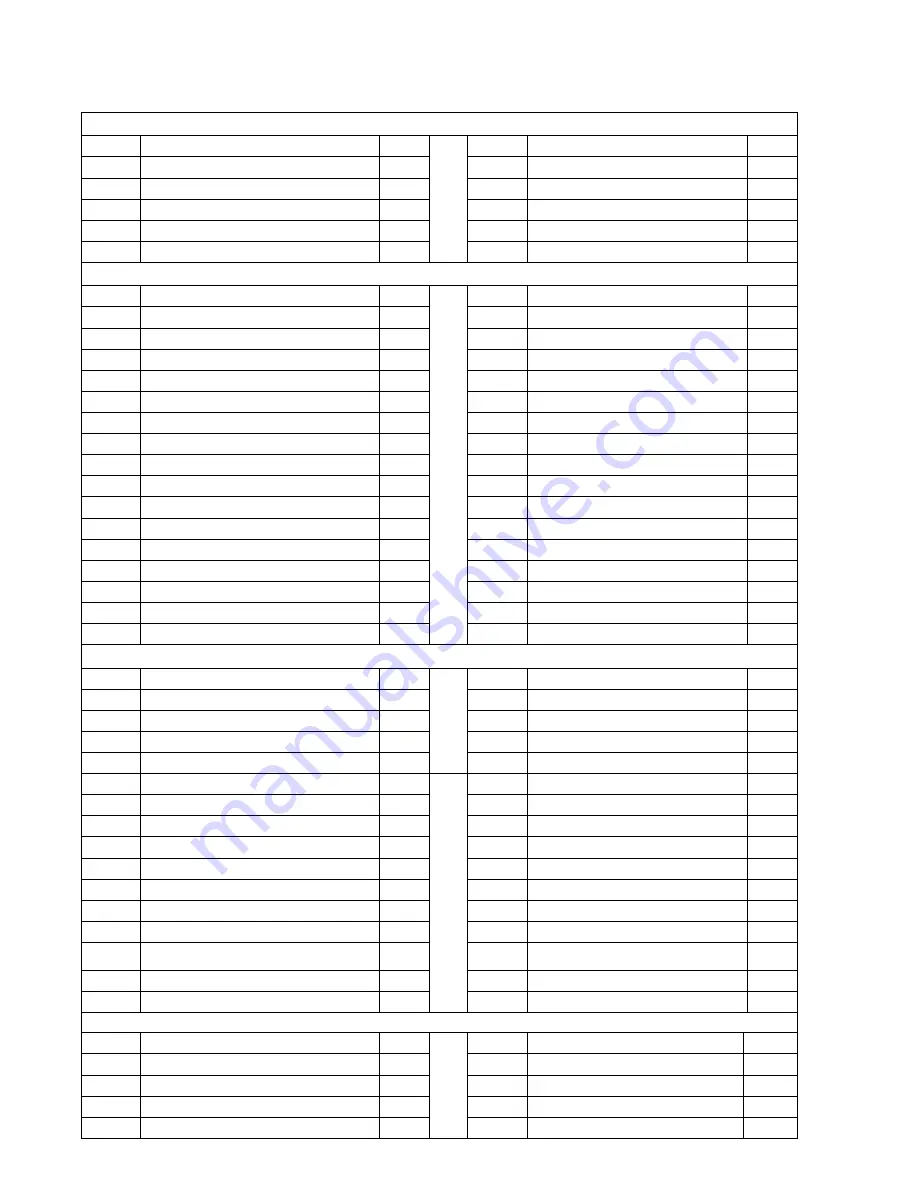

A. Welding parts

No.

Description

QTY

No.

Description

QTY

A1

Main frame

1

A5

Incline Frame

1

A2

Base frame

1

A6

滤波器支撑座

1

A3L

Left upright tube

1

A7

跑板加强管

1

A3R

Right upright tube

1

A11

Motor Barcket

1

A4

Handrail bracket

1

A13

Belt Guide

2

B. Plastic parts

No.

Description

QTY

No.

Description

QTY

B1

Computer chip

1

B17

Transport wheel

4

B1-1

Overlay

1

B1

8

Silicon oil

1

B1-2

Membrane key

1

B20

Protecting wire plug

1

B1-3

Computer panel

1

B21

Square plug

4

B2

Computer cover

1

B22

Left motor side cover

1

B3

Handrail foam

2

B23

Right motor side cover

1

B4

Plug

2

B26

Cushion

2

B6

Transport wheel

2

B27

New cushion

4

B8

Flat pad

4

B31

Rubber pad

2

B9

Horseshoe pads

2

B41L

Left speaker bottom cover

1

B11L

Left side cover

1

B41R

Left speaker bottom cover

1

B11R

Right side cover

1

B42

Handrail plug

2

B13

Motor cover

1

B43

PVC Buffer

2

B15

Side rails

2

B44

EVA pad

1

B16L

Left end cap

1

B77

EVA pad

4

B16R

Right end cap

1

B80

Motor decoration cover

1

C. Electric and drive parts

No.

Description

QTY

No.

Description

QTY

C2

Running belt

1

C19

MP3 Line

1

C3

Rear roller

1

C20

Magnetic ring

1

C4

Front roller

1

C21

Inductance

1

C5

Running board

1

C22

Filter

1

C6

Cylinder

1

C23

Overload protector

1

C7

Motor belt

1

C25

AC motor

1

C8

Power switch

1

C26

Inverter (AC controller)

1

C10

Left short keys

1

C27

Single cord (Black 300)

2

C11

Right short keys

1

C31

Single cord (Red 150)

2

C12

Incline Motor

1

C32

Single cord (Black 150)

1

C13

Safety key

1

C33

Grounding cable

1

C14

Single cord (Red 300)

1

C34

Outlet

1

C15

Power cable

1

C35

Single cord

(

CE

set

)

1

C16

Upper cable

1

C37

Chest belt

1

C17

Lower cable

1

D. Hardware parts

No.

Description

QTY

No.

Description

QTY

D1

Cross head with allen wrench T6

1

D33

Hex round head bolt M8*55

1

D2

Allen wrench T6

1

D34

Hex round head bolt M8*60

2

D4

Round hex bolt M10*65

2

D36

Cross head bolt M6*25

4

D6

Round hex bolt M8*50

2

D39

Cross head bolt M6*40

4

20