❏ ❏

2. Slide the die-cut 1/8” ply

LE Jigs

over

the dowels, with the flat edge towards the

sheeted (bottom) side of the wing.

❏ ❏

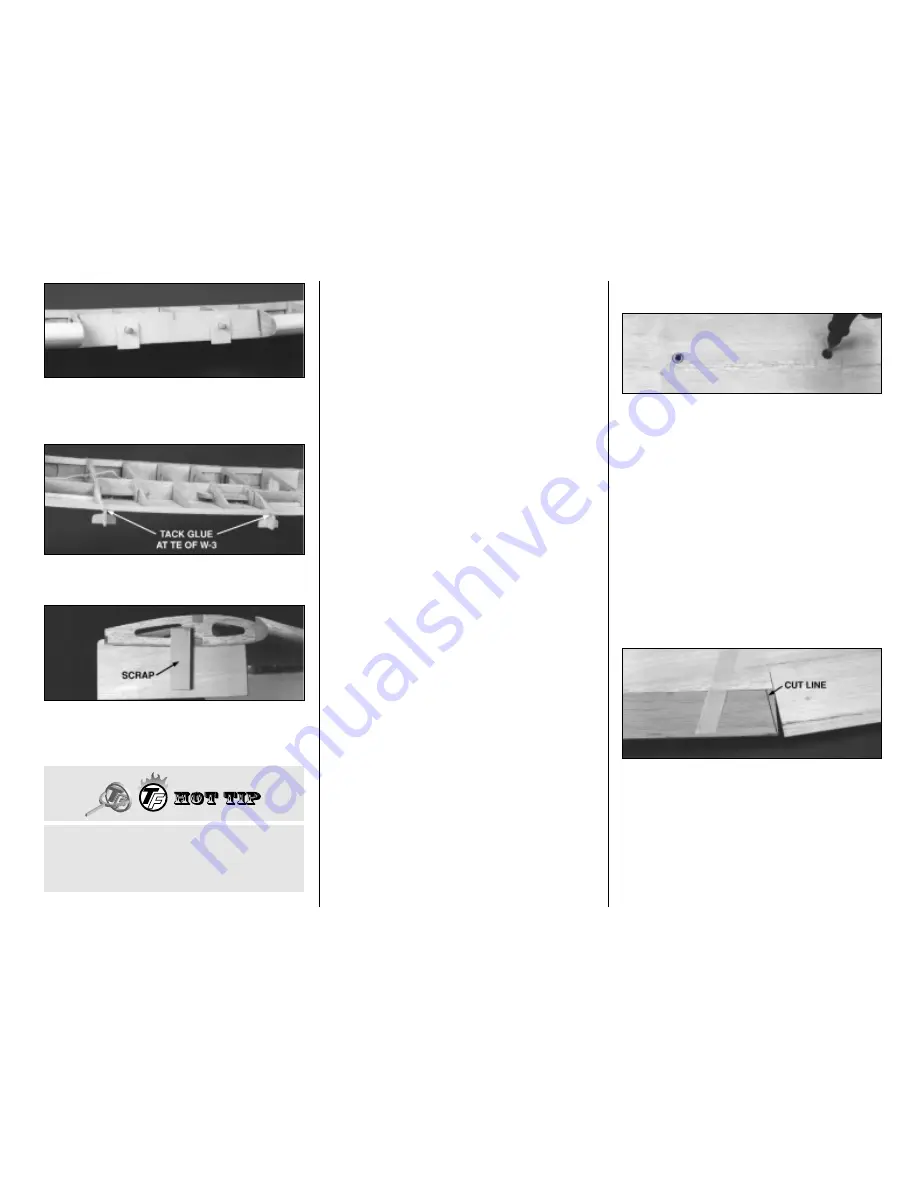

3. Tack glue the die-cut 1/8” ply

TE Jigs

to

the sheeting at the TE of W-3.

❏ ❏

4. Place a die-cut 1/8” plywood

Tip Jig

under each W-14 rib with the raised tip of the jig

butting up to the TE spar. Tack glue it in place.

NOTE: Use the same procedure to sheet the

top of the wing as you used for the bottom.

❏ ❏

5. Cut the top

Center Panel Skin

from the

skin you made earlier. Remember that it should

line up with the dividing line between ribs W-3

and W-4. When satisfied with the fit, glue it in

place with thick CA.

❏ ❏

6. Check the fit of an outboard skin to the

wing structure. Make adjustments if required to

fit flush with the LE and Center Panel. Sand a

slight bevel to the edge of the skin that will

contact the LE to allow for a better gluing

surface. Use thick CA to glue the skin in

position. Hold the skin firmly in place while the

CA cures.

Magazines make good weights. Wick

thin CA along the LE seam, wiping off any

excess CA before it hardens.

❏ ❏

7. Repeat step 6 for the other outer panel.

❏ ❏

8. Measure, cut and glue a 1/16” x 3” x 36”

balsa sheet to fit over the Flaps and the

openings at the aft edge of the wing skins, as

you did for the bottom of the wing.

At this point you should have the main wing

structure fully sheeted. You may now remove all

Jig par ts from the wing and sand off any

glue marks.

❏ ❏

1. Trim the sheeting where it protrudes past

the edge of the structure.

❏ ❏

2. Sand the wing

Leading Edge

until it

blends well with the sheeting to for m a

smooth airfoil.

❏ ❏

3. Square off the wing tips with a T-bar.

❏ ❏

4. Use a pointed piece of wire to mark the

holes for the wing bolts from the bottom,

through

the top wing skin. Use a hobby knife to

carefully cut a 1/4” hole in the sheeting around

the points you marked. Insert one of the 1/4”

nylon wing bolts through the wing from the top,

and trace around the head with a pen. Enlarge

the holes to the circles you just drew to allow the

wing mounting bolts to seat against the wing

mounting plates. Use a round file or Moto-Tool

and grinding drum to avoid tearing the sheeting.

IMPORTANT: The Ailerons must be fitted to

the wing and the hinge bevels sanded

before installing the wing tips or cutting the

flaps loose.

❏ ❏

5. Tape a tapered 2-3/32” x 21” balsa

Aileron

to the

Outer Aft Spar

with one end

against W-7.

Don’t be alarmed if the Aileron TE

is higher than the TE at W-7; this will be taken

care of when the aileron LE is tapered. Draw a

line on the Aileron, parallel to the edge of W-7.

Remove the Aileron, then cut and sand it to this

line. Check the fit and make any minor

corrections as needed.

WING COMPLETION

Glue a piece of scrap ply to the side of the jig

and also to the W-14 ribs (as shown here) to

prevent the jig from moving or having to glue it

to the sheeting.

25

Summary of Contents for CESSNA 182 SKYLANE

Page 8: ...8 DIE CUT PATTERNS ...