8

c

3

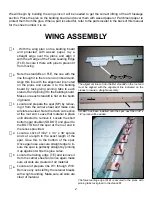

Temporarily secure the aileron assembly

to the wing with pins carefully centering it

in the trailing edge. Use a soft lead pen-

cil to mark the aileron assembly at the root

end and along the leading edge, top and

bottom. Use these lines to guide you when

you shape the ailerons. Plane and sand the

ailerons to shape.

c

5

c

4

Marking the aileron for shaping to the contour of the wing.

Mark the leading edge top and bottom as well as both ends.

The tip can be marked by laying a straight edge on the tip and

projecting a line over the end of the aileron.

Plane a chamfer on both sides of the lead-

ing edge of about 20 degrees but leave

about a 1/16” flat at the center for hinging.

Use a sharp X-Acto knife to open up the

slots in the trailing edge for the aileron hing-

es. The slots should be open all the way

through FLE.

c

6

Test fit the ailerons to the wing with the CA

Hinges. The aileron control horns will be in-

stalled after covering.

c

2

c

1

Locate all the belly pan components, BP-

1, BP-3, BP-5, BP-7, BP-9, BP-10 and BP-

11. Also the formed belly pan plastic parts.

Note that BP-11 terminates in an angle at

one end, this is the AFT end. Starting at the

front or opposite end install and glue BP-1

to BP-11. Install BP-3, BP-5, BP-7 and BP-9

from the front to the back. Install and glue

BP-10 at the angles end.

Belly pan formers attached to the belly pan keel. Use only

Pacer 560 canopy glue to attach this structure to the plastic

belly pan.

Locate the plastic formed belly pan. Note at

the sides where it changes from a curved

surface to a straight side. Use the side of

a pencil lead along this edge to define it.

Trim off the excess plastic from the sides.

Leave a little excess for final fitting. Leave

both ends for now.

c

3

Test fit the balsa frame work into the plas

-

tic pan. You will need to sand a bevel in

the edge of BP-10 so all the formers will fit

snugly to the plastic belly pan. To glue any-

thing to a flexible plastic part such as his you

need a glue that will remain flex able or it

will break away from the part. Two adhesive

that are excellent for this purpose are Pace

Formula 560 (Also called canopy glue) and

a glue called Grafter’s Pick which is a fabric

Rough trim the sides of the belly pan form using the line cre

-

ated by rubbing the side of a soft lead pencil against ridge on

the sides.

ASSEMBLING THE BELLY PAN